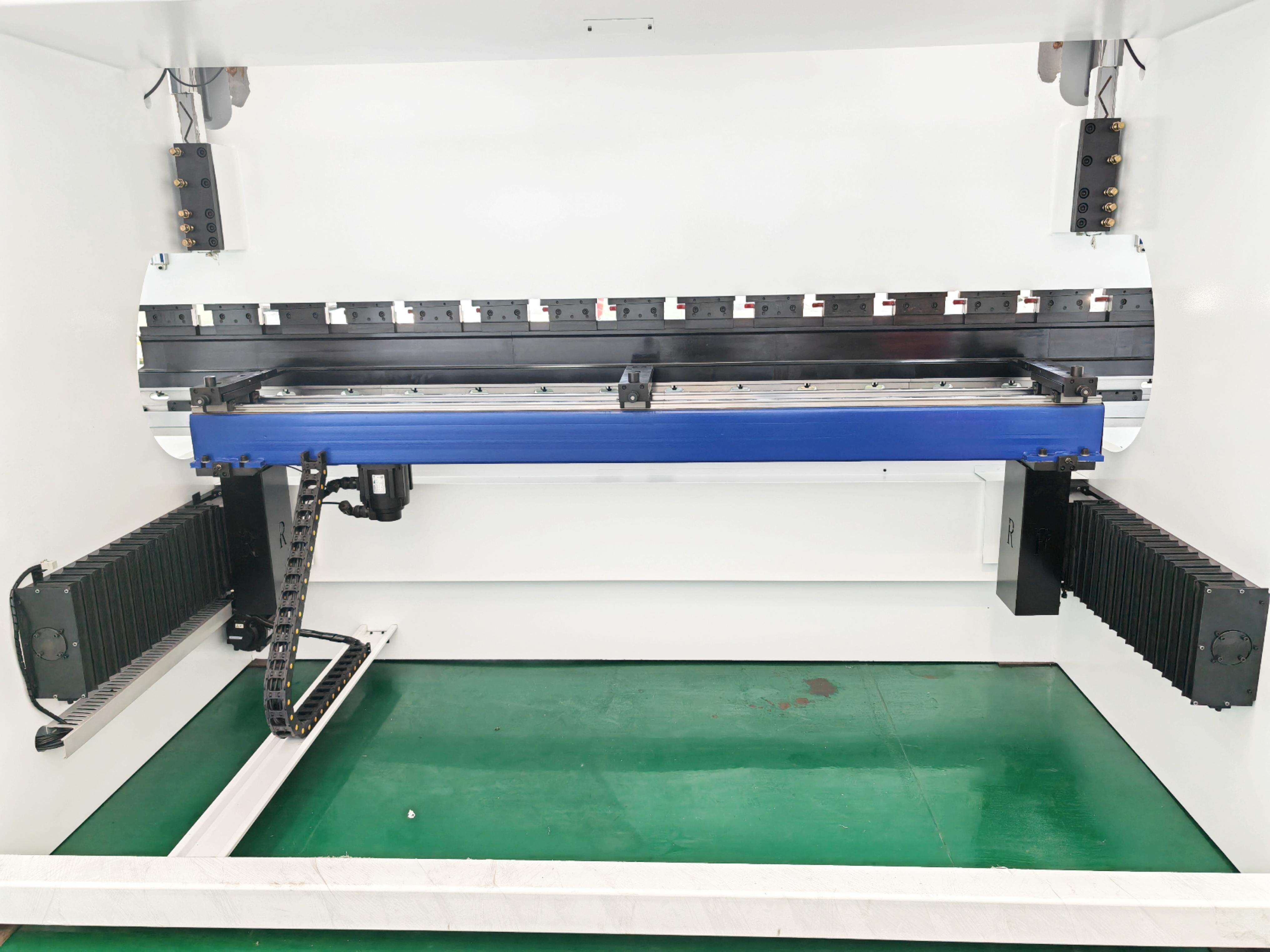

steel cutting bending machine

The steel cutting bending machine represents a sophisticated piece of industrial equipment designed to perform multiple metalworking operations efficiently. This versatile machine combines cutting and bending capabilities in a single unit, streamlining the metal fabrication process. At its core, the machine utilizes advanced hydraulic systems and precision control mechanisms to achieve accurate cuts and bends in various steel materials, including sheet metal, pipes, and structural steel. The cutting mechanism employs high-grade steel blades or plasma technology, capable of clean, precise cuts across different material thicknesses. The bending component features adjustable dies and pressure settings, allowing for angles ranging from slight bends to complex shapes. Modern steel cutting bending machines incorporate computerized numerical control (CNC) systems, enabling automated operation and consistent results. These machines typically feature user-friendly interfaces, programmable memory for recurring tasks, and safety mechanisms to protect operators. They can handle materials of various specifications, from thin sheets to thick plates, making them invaluable in industries such as construction, automotive manufacturing, and metal fabrication workshops. The machine's ability to perform multiple operations reduces the need for separate equipment, saving both space and operational costs while maintaining high precision standards.