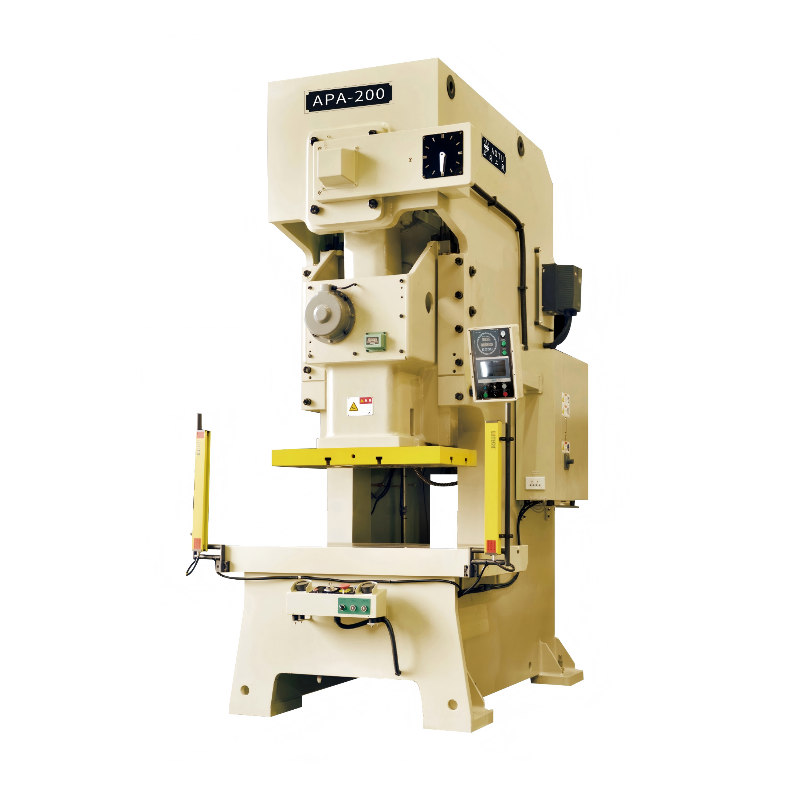

- Overview

- Related Products

Standard accessories

| - Inverter | - Electric Slide adjust Device( over 60T) | - Speed Indicator |

| -Touch pad | - Mechanical Die Height Indicator(60T and below 60T) | - Air source Receptacle |

| - Preset Counter | - Electric Die Height Indicator( over 60T) | - Second Fall Protection Device |

| - Forejudge Counter | - Balance Device | - Misfeed Detection Device |

| - Electric cam | - Crank Angle Indicator | - Power Socket |

| - Hydraulic Over-load Protector | - Anti Vibration Press Mount | - Maintenance Tool Box |

| - Mechanical Slide Adjust Device(60T and below 60T) | - Operation Manual |

Optional accessories

| -Auto grease pump(Standard for over 110T) | -Die Room Light |

| -Pneumatic Die Cushion Device | -Safety light sensor |

| - Foot Switch | -Feeder |

| - Quick Die Change Device | -Uncoiler |

| (Die Lifter, Clamp And Die Arm) | -Straightener |

| - Slide Knock-out Device | -Mechanism Hand |

Technical parameter

Model |

APA-25 |

APA-35 |

APA-45 |

APA-60 |

APA-80 |

|||||||

V Type |

H Type |

V Type |

H Type |

V Type |

H Type |

V Type |

H Type |

V Type |

H Type |

|||

Capacity |

Ton |

25 |

35 |

60 |

60 |

80 |

||||||

Rated Tonnage point |

mm |

3.2 |

1.5 |

3.2 |

1.6 |

3.2 |

1.6 |

4 |

2 |

4 |

2 |

|

Stroke Per |

Variable |

SPM |

60~140 |

130~200 |

40~120 |

110~180 |

40~100 |

100~150 |

35~90 |

80~120 |

35~80 |

80~120 |

Fixed |

SPM |

110 |

85 |

75 |

65 |

65 |

||||||

Stroke |

mm |

60 |

30 |

70 |

40 |

80 |

50 |

120 |

60 |

150 |

70 |

|

Die Height |

mm |

200 |

215 |

220 |

235 |

250 |

265 |

310 |

340 |

340 |

380 |

|

Slide adjustment |

mm |

50 |

55 |

60 |

75 |

80 |

||||||

Slide area |

mm |

300x230x50 |

360x250x50 |

400×300×60 |

500×360×70 |

560×420×70 |

||||||

Bolster Area |

mm |

680x300x70 |

800x400x70 |

850×440×80 |

900×500×80 |

1000×550×90 |

||||||

Shank Hole |

mm |

φ38.1 |

φ38.1 |

φ38.1 |

φ50 |

φ50 |

||||||

Main Motor |

kw.p |

4x4 |

4x4 |

4x4 |

5.5x4 |

7.5x4 |

||||||

Slide Adjust Device |

|

Manual operation |

Electric driving |

|||||||||

Air Pressure |

kg/cm² |

6 |

6 |

6 |

6 |

6 |

||||||

Presses Precision |

|

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

||||||

Presses Dimension |

mm |

1280x850x2200 |

1380x900x2400 |

1600×950×2500 |

1600×1000×2800 |

1800×1180×3000 |

||||||

Die Cushion Capacity |

Ton |

- |

2.3 |

2.3 |

3.6 |

3.6 |

||||||

Die Cushion Stroke |

mm |

- |

50 |

50 |

70 |

70 |

||||||

Die Cushion Effective Area |

mm² |

- |

300x230 |

300×230 |

350×300 |

450×310 |

||||||

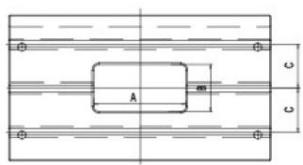

| Slide Area work up | Bolster Area work down | ||

|

|

|

|

|

|

||

Model |

APA-110 |

APA-160 |

APA-200 |

APA-260 |

APA-315 |

APA-400 |

|||||||

V Type |

H Type |

V Type |

H Type |

V Type |

H Type |

V Type |

H Type |

V Type |

H Type |

V Type H Type |

|||

Capacity |

Ton |

110 |

160 |

200 |

260 |

315 |

400 |

||||||

Rated Tonnage point |

mm |

6 |

3 |

6 |

3 |

6 |

3 |

7 |

3.5 |

8 |

4 |

8 |

|

Stroke Per |

Variable |

SPM |

30~60 |

60~90 |

20~50 |

40~70 |

20~50 |

50~70 |

20~40 |

40~50 |

20~40 |

40~50 |

20~35 |

Fixed |

SPM |

50 |

35 |

35 |

30 |

30 |

30 |

||||||

Stroke |

mm |

180 |

80 |

200 |

90 |

200 |

100 |

250 |

150 |

250 |

150 |

300 |

|

Die Height |

mm |

360 |

410 |

460 |

510 |

460 |

510 |

500 |

550 |

500 |

550 |

550 |

|

Slide adjustment |

mm |

80 |

100 |

110 |

120 |

120 |

120 |

||||||

Slide area |

mm |

650×470×80 |

700×550×90 |

850×630×90 |

950×700×100 |

950×700×100 |

1050×840×100 |

||||||

Bolster Area |

mm |

1150×600×110 |

1250×800×140 |

1400×820×160 |

1500×840×180 |

1500×840×200 |

1800×950×200 |

||||||

Shank Hole |

mm |

φ50 |

φ65 |

φ65 |

φ65 |

φ65 |

φ70 |

||||||

Main Motor |

kw.p |

11x4 |

15×4 |

18.5×4 |

22×4 |

30×4 |

37×4 |

||||||

Slide Adjust Device |

|

Electric driving |

|||||||||||

Air Pressure |

kg/cm² |

6 |

6 |

6 |

6 |

6 |

6 |

||||||

Presses Precision |

|

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

GB(JIS)1class |

||||||

Presses Dimension |

mm |

1900×1300×3200 |

2300×1400×3800 |

2615×1690×4075 |

2780×1850×4470 |

2780×1850×4500 |

3250×2150×4600 |

||||||

Die Cushion Capacity |

Ton |

6.3 |

10 |

14 |

14 |

14 |

14 |

||||||

Die Cushion Stroke |

mm |

80 |

80 |

100 |

100 |

100 |

100 |

||||||

Die Cushion Effective Area |

mm² |

500×350 |

650×420 |

710×480 |

810×480 |

810×480 |

810×480 |

||||||