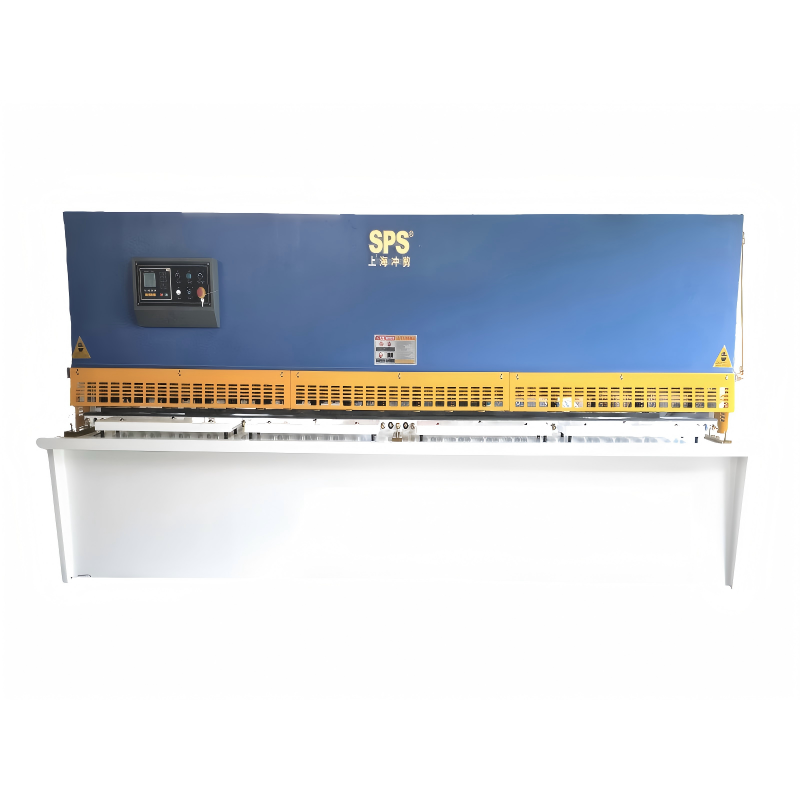

Open-type One-point Press(JH21)

Adopting dry or wet pneumatic friction clutch brakes, the action is sensitive and reliable.

- Overview

- Related Products

Product features

-Adopting dry or wet pneumatic friction clutch brakes, the action is sensitive and reliable.

-The welded steel plate body has good rigidity and stable accuracy.

-Precision grinding of large gears and gear shafts, resulting in low operating noise of machine tools.

-The slider six sided guide rail is equipped with an air pressure balancing device, ensuring smooth operation and accurate accuracy.

-Using hydraulic overload protection device to efectively protect the press and mold.

-The use of PLC control with automatic feeding device can form a single machine automated or multi machine automated stamping production line.travel, which are more suitable for stamping process requirements and improving.

-In addition to constant speed, this model has two options for continuously variable production efciency.

Technical parameter

Model |

JH21- 25 |

JH21- 45 |

JH21- 60 |

JH21- 80 |

JH21- 125 |

JH21- 160 |

JH21- 200 |

JH21- 250 |

JH21- 315 |

JH21- 400 |

JH21- 500 |

|||

Nominal pressure of slider |

KN |

250 |

450 |

600 |

800 |

1250 |

1600 |

2000 |

2500 |

3150 |

4000 |

5000 |

||

Nominal pressure of slider |

mm |

2.8/2 |

3.2/2 |

4/2.5 |

4.5/2.5 |

5/3 |

6/3.5 |

7/3.5 |

7/4 |

7/4 |

8/4.5 |

8 |

||

Slide stroke |

mm |

80/50 |

3.2/2 |

140/80 |

160/90 |

180/100 |

200/120 |

250/130 |

250/150 |

250/150 |

280/180 |

280 |

||

Number of trips |

fixed |

|

100 |

80 |

70 |

60 |

65 |

45 |

45 |

40 |

40 |

35 |

25 |

|

variable |

L |

|

60-100 |

50-80 |

40-70 |

40-60 |

35-65 |

25-45 |

25-45 |

25-40 |

20-40 |

20-35 |

/ |

|

S |

|

80-140 |

70/130 |

60-110 |

55-100 |

50-95 |

40-75 |

35-60 |

30-55 |

30-55 |

30-50 |

/ |

||

Maximum enclosed height |

mm |

250/265 |

270/300 |

300/330 |

320/355 |

350/390 |

400/440 |

450/510 |

500/550 |

500/550 |

530/580 |

550 |

||

Maximum enclosed height |

mm |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

120 |

120 |

120 |

||

Maximum enclosed height |

mm |

210 |

225 |

270 |

310 |

350 |

390 |

430 |

450 |

450 |

480 |

480 |

||

Workbench |

about |

mm |

700 |

810 |

870 |

950 |

1100 |

1170 |

1390 |

1500 |

1540 |

1700 |

1800 |

|

around |

mm |

400 |

440 |

520 |

600 |

680 |

760 |

840 |

880 |

880 |

940 |

940 |

||

thickness |

mm |

80 |

110 |

130 |

140 |

155 |

165 |

180 |

190 |

190 |

200 |

250 |

||

Bottom of |

about |

mm |

360 |

410 |

480 |

540 |

620 |

700 |

880 |

950 |

950 |

1000 |

1000 |

|

around |

mm |

250 |

340 |

400 |

460 |

520 |

580 |

650 |

700 |

700 |

750 |

750 |

||

|

diameter |

mm |

40 |

50 |

50 |

50 |

70 |

70 |

70 |

70 |

70 |

70 |

70 |

|

depth |

mm |

60 |

60 |

70 |

70 |

80 |

100 |

100 |

100 |

100 |

100 |

100 |

||

|

about |

mm |

690 |

745 |

840 |

920 |

1040 |

1140 |

1360 |

1460 |

1500 |

1550 |

1650 |

|

around |

mm |

1080 |

1190 |

1100 |

1235 |

1510 |

1660 |

2020 |

2150 |

2320 |

2500 |

2585 |

||

External |

about |

mm |

830 |

1075 |

1200 |

1280 |

1220 |

1375 |

1690 |

1680 |

1720 |

1790 |

1770 |

|

around |

mm |

1390 |

1675 |

1685 |

1990 |

2125 |

2355 |

2580 |

2820 |

3060 |

3150 |

3105 |

||

high |

mm |

2120 |

2391 |

2560 |

2725 |

3055 |

3215 |

3810 |

3915 |

3957 |

4320 |

4325 |

||

gasbag |

Ejection ability |

KN |

- |

23 |

35 |

63 |

80 |

100 |

140 |

140 |

140 |

140 |

140 |

|

stroke |

mm |

- |

60 |

70 |

80 |

90 |

100 |

100 |

100 |

100 |

100 |

100 |

||

Roof area |

mm |

- |

300*220 |

350*220 |

410*220 |

460*340 |

540*420 |

560*420 |

560*420 |

560*420 |

560*420 |

560*420 |

||

Motor power(fixed/variable) |

KW |

2.2-4P |

5.5-4P |

5.5-4P |

7.5-4P |

7.5-4P |

15-4P |

15-4P |

22-4P |

30-4P |

37-6P |

37-4P |

||

weight |

Kg |

2600 |

3500 |

5500 |

7500 |

11000 |

15200 |

20500 |

23500 |

30000 |

35000 |

45000 |

||

Using air pressure |

Mpa |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

||

Standard accessories /Optional accessories

Standard accessories |

Standard |

Optional accessories |

Standard |

Hydraulic Overload Protection Device |

● |

Air Cushion Die Pad Device |

○ |

Die Height Adjustment Device (Manual for ≤45T, Electric for ≥60T) |

● |

Photoelectric Safety Protection Device |

○ |

Die Height Indicator (Mechanical for ≤45T, Digital Display for ≥60T) |

● |

Electronic Cam Control System (Standard for ≥250T) |

○ |

Slide and Die Balancing Device |

● |

Portable Two-hand Control Box (Standard for ≥250T) |

○ |

Air Blow-off Device |

● |

Automatic Feed Output Shaft |

○ |

Anti-vibration Pad |

● |

Wet Clutch |

○ |

Dry Clutch |

● |

Double Stroke Prevention Device |

○ |

Automatic Lubrication System |

● |

Frequency Variety Adjustment Device (Variable Frequency Drive or Speed-regulating Motor) |

○ |

Work Counter |

● |

Preset Counter |

○ |

Rotary Cam Controller |

● |

Portable Electric Control Cabinet (Standard for ≥250T) |

○ |

Crank Angle Indicator |

● |

Foot Pedal Switch |

○ |

Knockout Device |

● |

Automatic Feeder |

○ |

|

|

Die Lighting Device |

○ |

|

|

Quick Die Change Device |

○ |