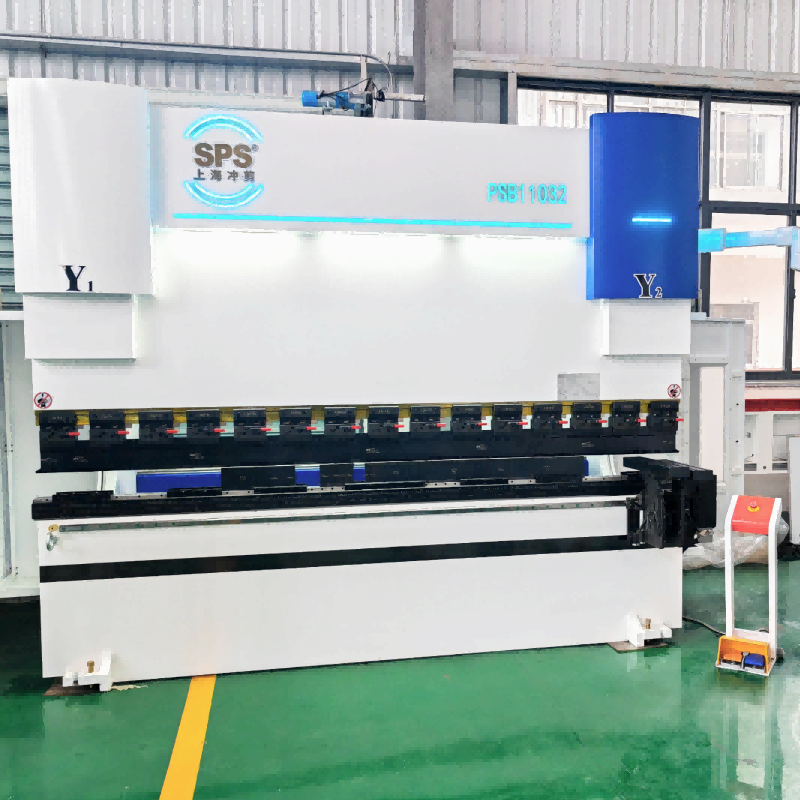

PSM Hybrid CNC Press Brake

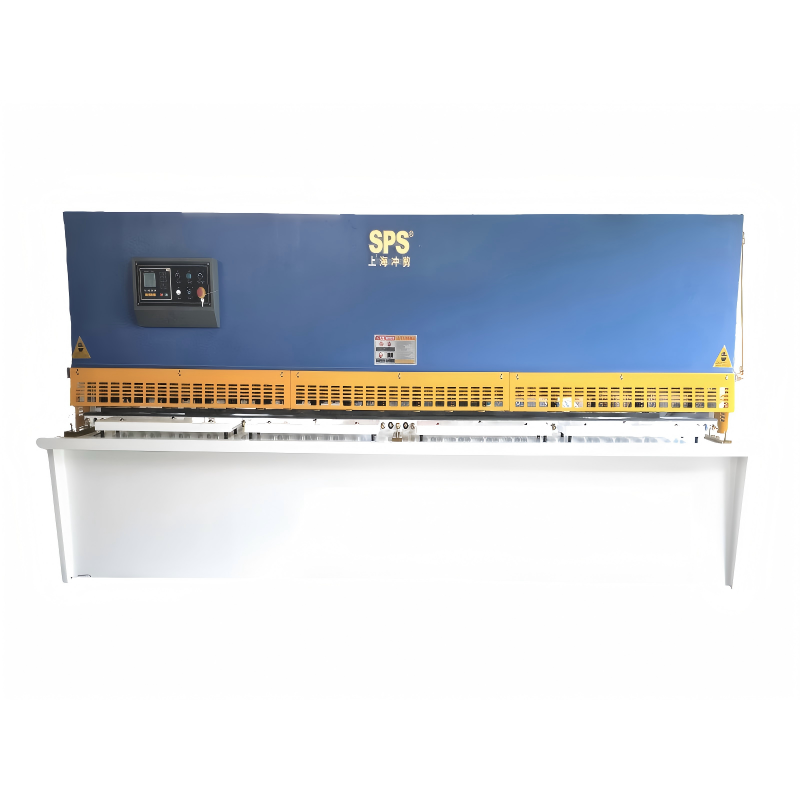

SPS ® PSM Hybrid CNC Press Brake adopts Pump control technology replaces conventional valve control technology.

- Overview

- Related Products

SPS ® PSM Hybrid CNC Press Brake adopts Pump control technology replaces conventional valve control technology. The Dual-Servo Oil-Electric Hybrid system controls the quick lowering, bending and return movements of Y1 and Y2 axes through a set of servo motors and servo pumps on the left and right sides. The movements are fast and stable, and the response speed greatly exceeds that of proportional valve control. Compared with PSA Electro-Hydro CNC Press Brake, hydraulic oil usage is reduced by 70%, energy efficiency increase 50%, and lower noise during operation.

|

● 24" Delem DA66s Control Unit l Taiwan ● HAVE ePrAx ® Series Bidirectional Servo Pump ● Y1, Y2, X, R, Z1, Z2 and V Crowningl ● Germany EMB Pipe Connector ● Estun Servo Main Motor ● Movable Stop Fingers on Double Linear Guide Rail ● HIWIN Ball Screw and Linear Guide Rail |

● Fast and Easy Tooling Change System ● France Schneider Electrics ● Korea Foot Pedal with Emergency Stop Button ● Spain Fagor Grating Ruler ● SPS Group High Precision Punch and Die ● Estun Servo Motor and Driver ● SPS Group High Precision Punch and Die |

|

|

|

|

|

Throat Depth SPS unique C-type frame design |

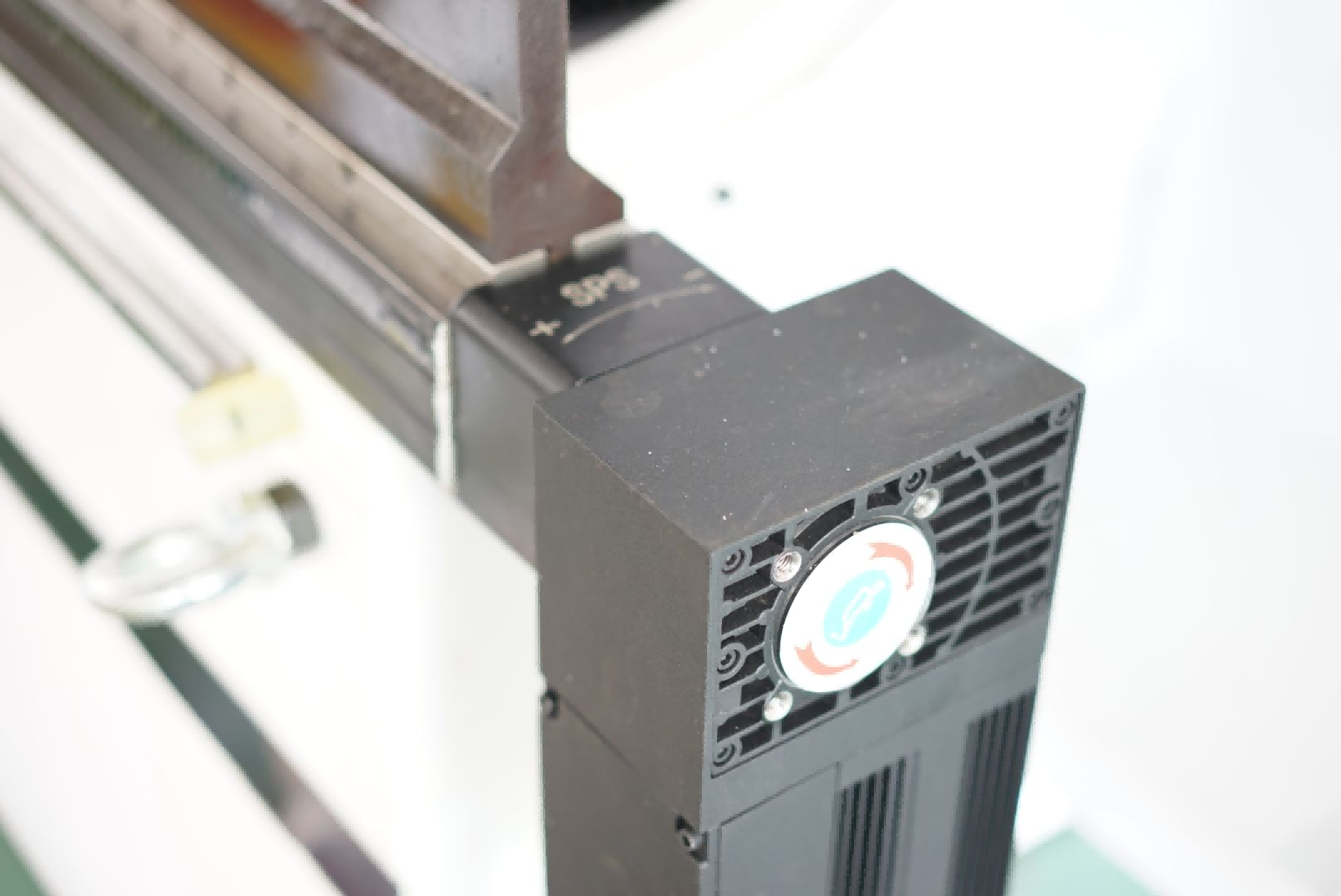

Hybrid Servo System HAVE ePrAx ® Series Bidirectional Servo Pump control system |

Schneider Electrics France Schneider main electrics and Estun servo driver |

Grating Ruler France Fagor Grating Ruler |

|

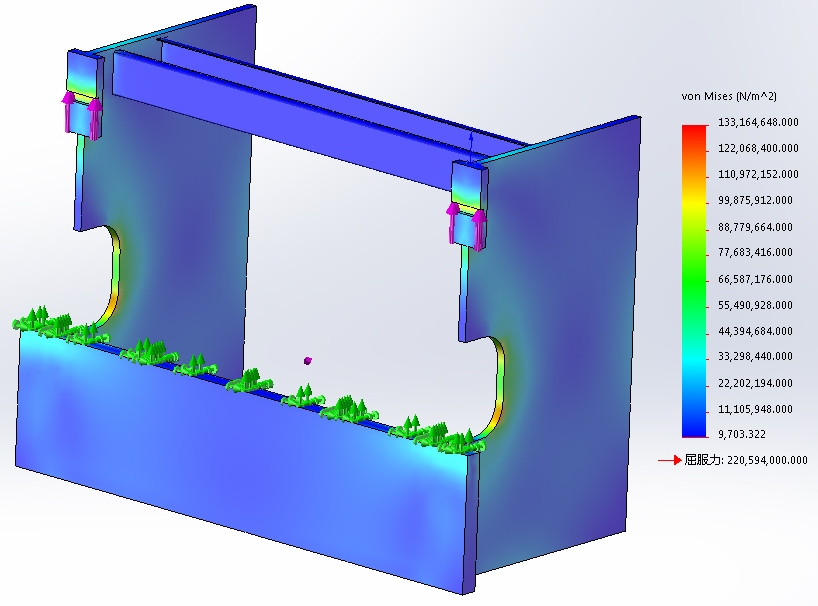

FEA & Stress Analysis

The CAE software SOLIDWORKS used to ensure reasonable frame deformation and high strength. The slider is annealed as a whole and processed as a whole with high precision, which can ensure stable precision for a long time.

|

|

|

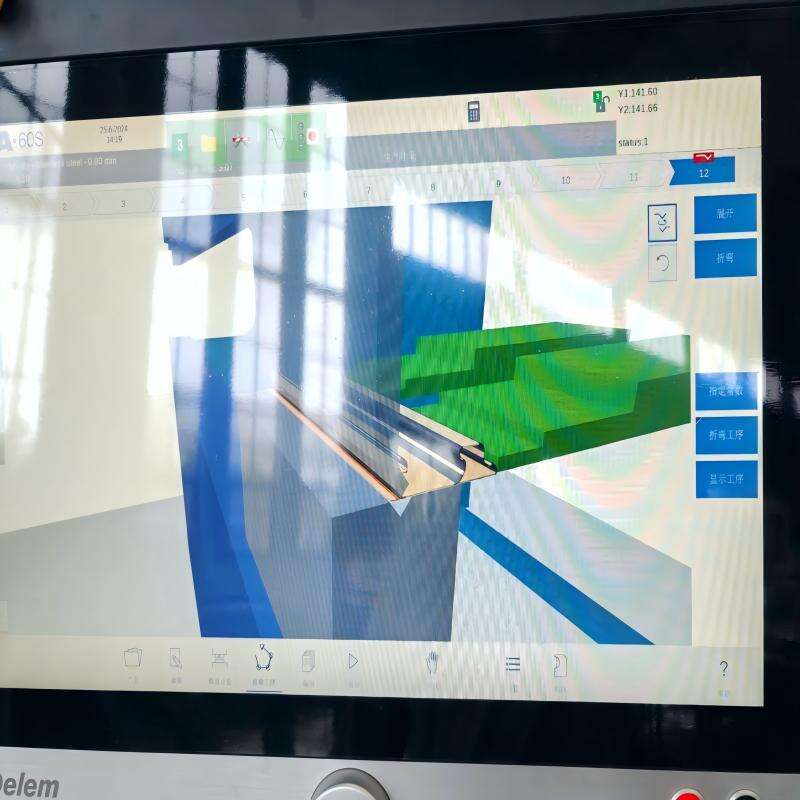

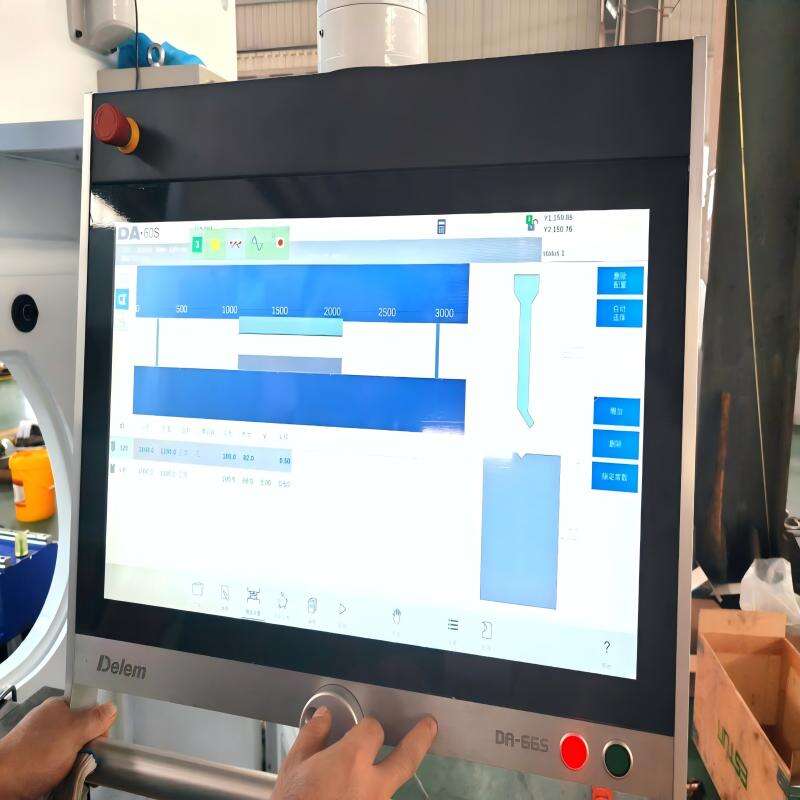

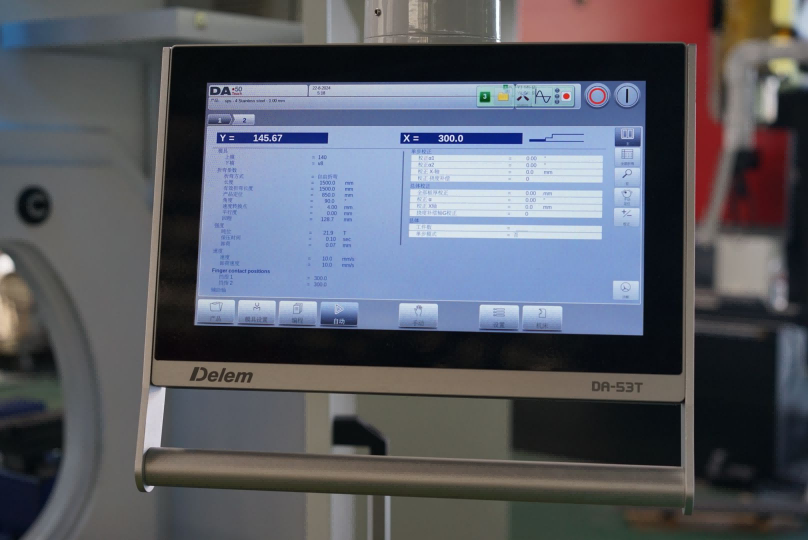

Delem DA66S Control Unit

24" high resolution colour TFT

2D graphic programming

3D machine representation, in simulation and production

USB, peripheral interfacing

User specific application Support within the control's multitasking environment

Sensor bending & correction interface

Profile-S2D offline software

|

|

|

SPS® Auto Crowning Table

The workbench is equipped with a deflection compensation mechanism to compensate for the deformation of the workbench and slider to ensure the accuracy of the workpiece. The adjustment method is mainly for the user to input a value to the CNC system based on the actual angle error of the workpiece being processed, and the CNC system will automatically adjust the compensation.

|

|

|

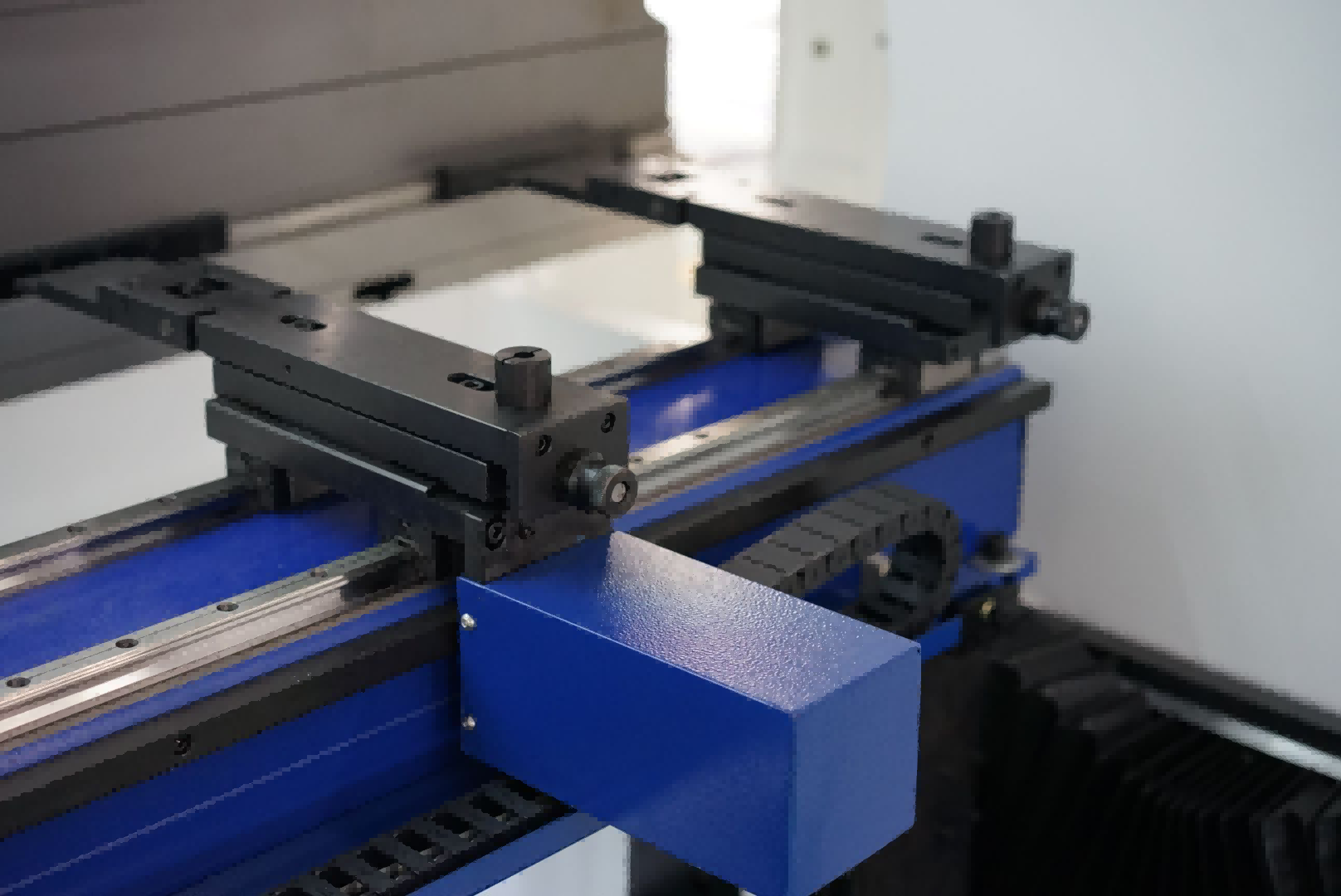

SPS® 4 Axes Backgauge

PSM Hybrid CNC Press Brake Backgauge is assembled by ball screw, linear guide rail, and motorized stopper finger.

It is equipped with CNC X-axis, R-axis, Z1 and Z2-axis as standard. The X-axis travel is 0-600mm. There are 4 pcs of stoppers on the stopper beam, two of which can be automaticlly moved left and right to stop the material according to different material width, and it has a manual fine-tuning structure. The back stopper beam is annealed and suitable for gantry processing center processing, with good stability and high precision.

|

|

Optional Components

|

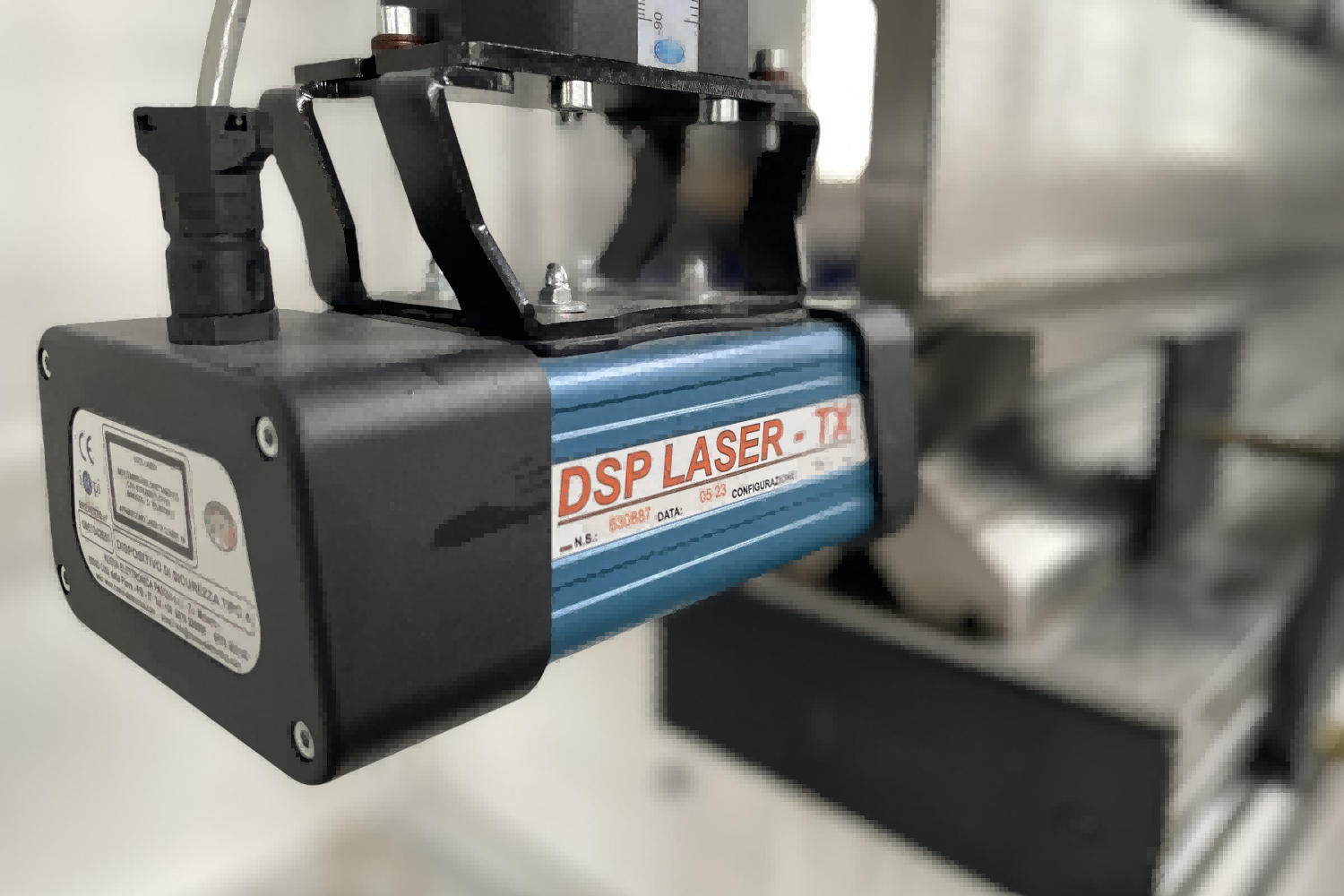

● DA66S 2D Programming ● Backgauge 6 Axes Device ● Italy DSP Laser Protection ● Auto Bending Follower Support ● Bending Angle Measurement |

● CE Economic Light Curtain ● High Precision Multi-V Die ● WILA Hydraulic Clamping System ● WILA Tooling and Worktable System ● DA53Tx, DA58T, DA66T, DA69T, CT8, CT12, CT15 |

|

|

|

|

|

Auto Bending Follower Suitable for various large-scale plate bending work, reducing the workload of operators and improving efficiency and precision |

DSP Laser Protection Europe CE Standard, Protection grade IP65, Safety level reaches CAT.4 and SIL3 |

CNC Controller SPS offers a full line control system of Delem, Cybelec, Esa, and other controllers according to your preference. |

Easy Fast Clamping We supply Wila, Amada and Double Side Fast Claming System. |

Technical Parameters

Model |

Bending Pressure |

Bending Length |

Polo Distance |

Throat Depth |

Slide Strokes |

Max Open Height |

Backgauge Travel |

Main Motor |

Dimension |

Kn |

Mm |

Mm |

Mm |

Mm |

Mm |

Mm |

Kw |

Mm |

|

PSM-63T2500 |

630 |

2500 |

2000 |

350 |

150 |

320 |

600 |

5.5 |

2700*1340*2000 |

PSM-80T2500 |

800 |

2500 |

2000 |

350 |

150 |

460 |

600 |

5.5 |

2800*1450*2450 |

PSM-110T3200 |

1100 |

3200 |

2700 |

400 |

200 |

480 |

600 |

7.5 |

3800*1800*2650 |

PSM-110T4000 |

1100 |

4000 |

3500 |

400 |

200 |

480 |

600 |

11 |

4600*1800*2650 |

PSM-130T3200 |

1300 |

3200 |

2700 |

400 |

200 |

480 |

600 |

11 |

3800*1800*2700 |

PSM-130T4000 |

1300 |

4000 |

3500 |

400 |

200 |

480 |

600 |

11 |

4600*1800*2700 |

PSM-170T3200 |

1700 |

3200 |

2700 |

450 |

200 |

480 |

600 |

15 |

3800*2050*2800 |

PSM-170T4000 |

1700 |

4000 |

3500 |

450 |

200 |

480 |

600 |

15 |

4600*2050*2800 |

PSM-220T3200 |

2200 |

3200 |

2700 |

450 |

200 |

480 |

600 |

18.5 |

3800*2100*2900 |

PSM-220T4000 |

2200 |

4000 |

3500 |

450 |

200 |

480 |

600 |

18.5 |

4600*2100*2900 |

PSM-220T5000 |

2200 |

5000 |

3900 |

450 |

200 |

540 |

600 |

18.5 |

5600*2100*2900 |

PSM-250T3200 |

2500 |

3200 |

2700 |

450 |

250 |

540 |

600 |

18.5 |

3500*2200*2900 |

PSM-250T4000 |

2500 |

4000 |

3500 |

450 |

250 |

540 |

600 |

22 |

4300*2200*2900 |

PSM-250T5000 |

2500 |

6000 |

4900 |

450 |

250 |

540 |

600 |

22 |

5400*2200*3100 |