PSN NC Press Brake E310P

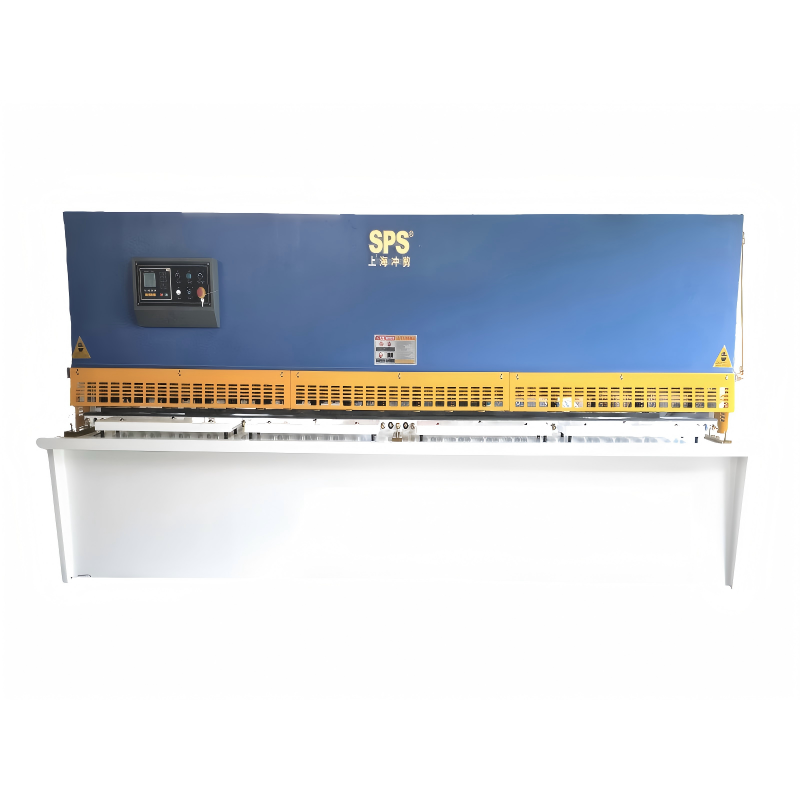

SPS ® PSN Torsion Bar NC Press brake machine is a general equipment for bending various metal sheets, while equip with different bending toolings, it can be folding into different workpieces.

- Overview

- Related Products

SPS ® PSN Torsion Bar NC Press brake machine is a general equipment for bending various metal sheets, while equip with different bending toolings, it can be folding into different workpieces. SPS sheet metal bending machine are widely used in shipbuilding, automobiles, vehicles, mining machinery, petroleum, electric power and other industries.

SPS ® NC type sheet metal press brake is mainly driven by 2 hydraulic cylinder to drive the slider to move the mold up and down. The machine has an integral structure and the frame is welded, which is easy to manufacture and install. The whole machine has good rigidity and high strength.

Standard Components

● E310P Control Unit |

● Taiwan HIWIN Ball Screw and Linear Guide Rail |

● Standard Y and X 2 Axis |

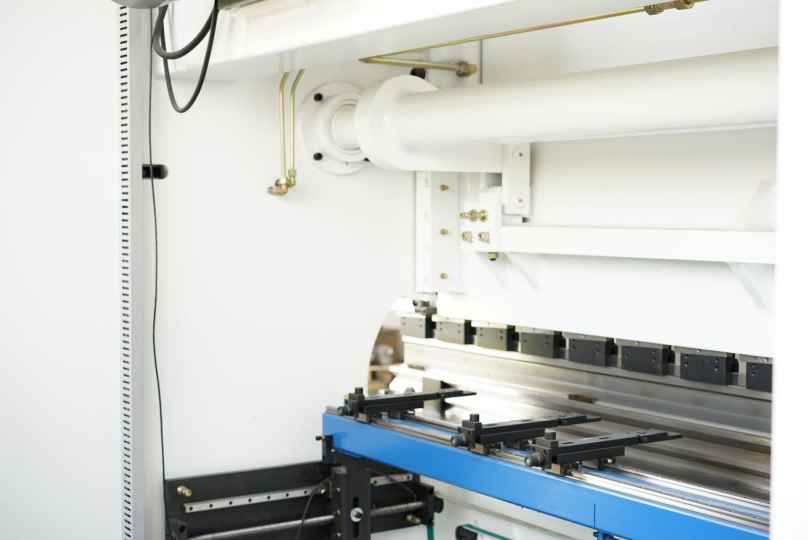

● Germany EMB Pipe Connector |

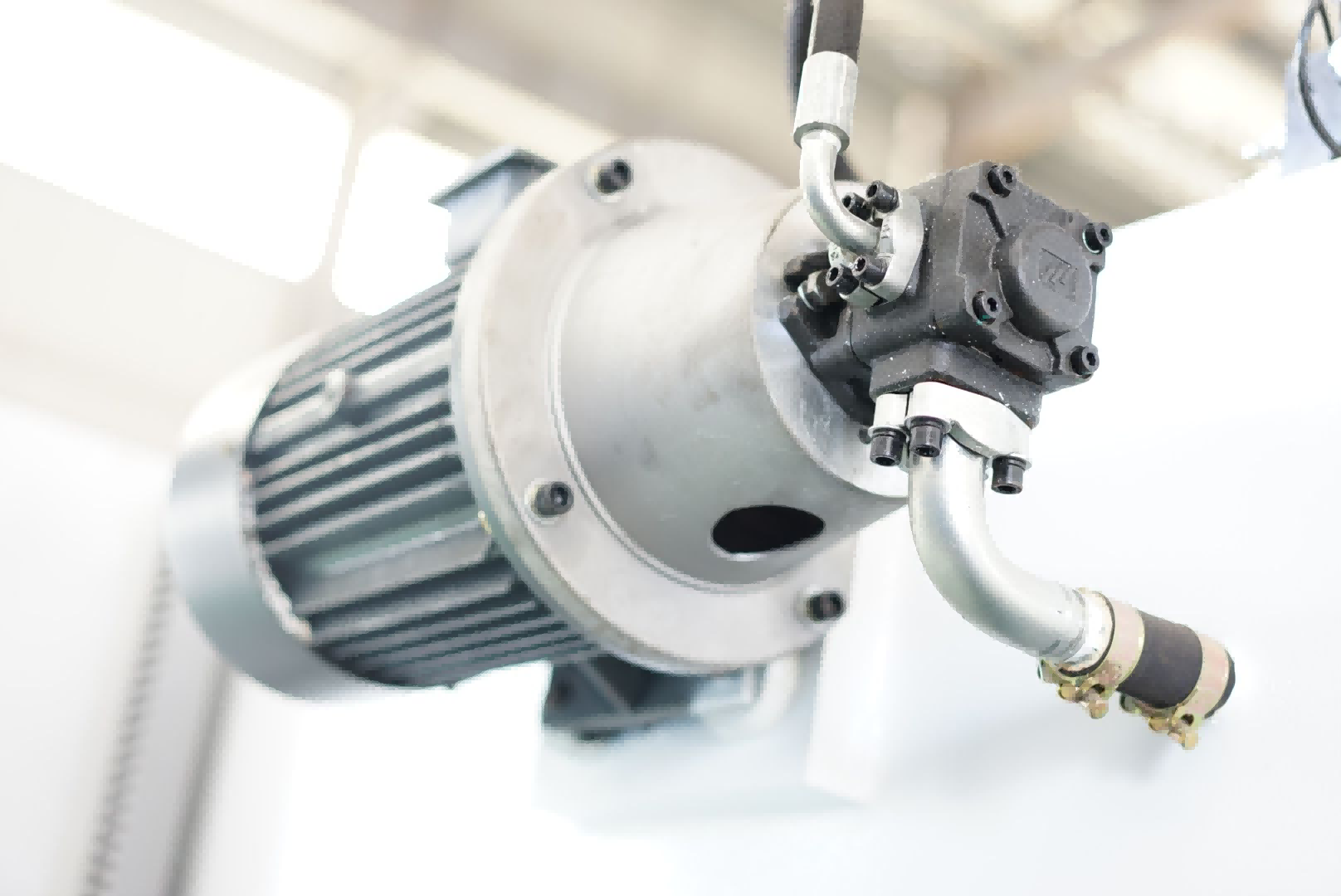

● Germany Siemens Main Motor |

● Movable Stop Fingers on Dual Linear Guide Rail |

● Germany Rexroth Hydraulic Valve |

● Japan NOK Sealings |

● France Schneider Electrics |

● Korea Foot Pedal with Emergency Stop Button |

● USA First/Sunny Oil Pump |

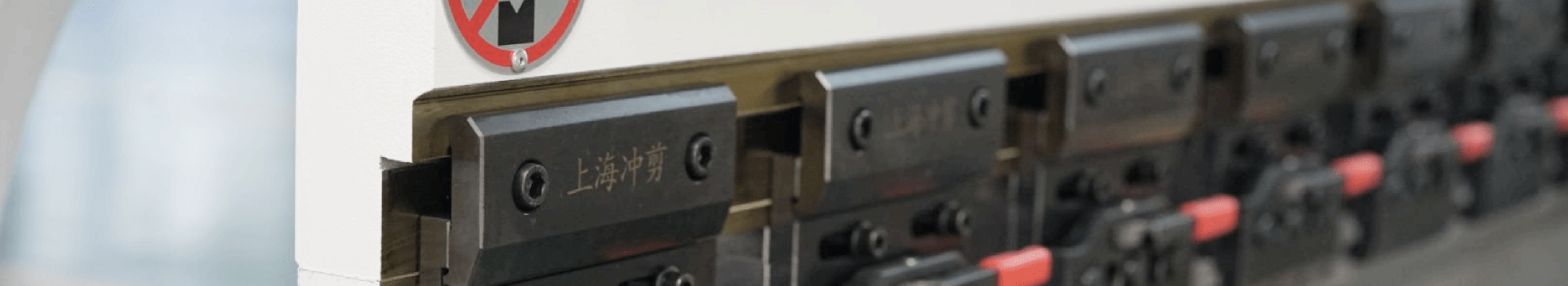

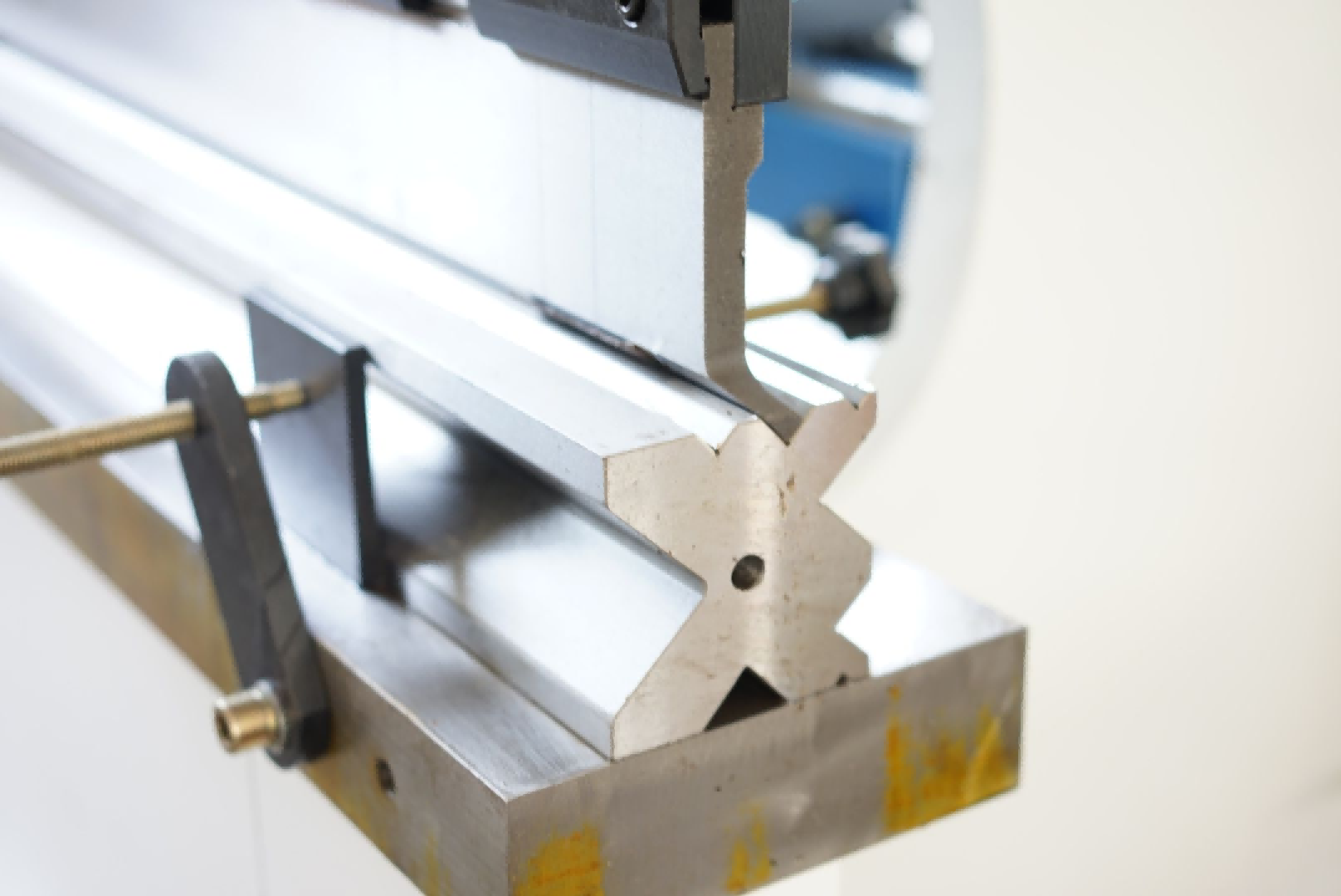

● Fast and Easy Tooling Change System |

● EasyCat servo motor and driver |

● SPS Group High Precision Punch and Die |

|

|

|

|

|

Torsin Bar Structure SPS stronger torsion bar strcure |

Siemens Main Motor High efficiency level reduces energy consumption and saves costs for the user. |

Rexroth Valve Famous hydraulic system can ensure the stability and enhancing highly the reliability of the machine |

Backgauge Stop Fingers Movable stop finger on double linear guide rail. |

|

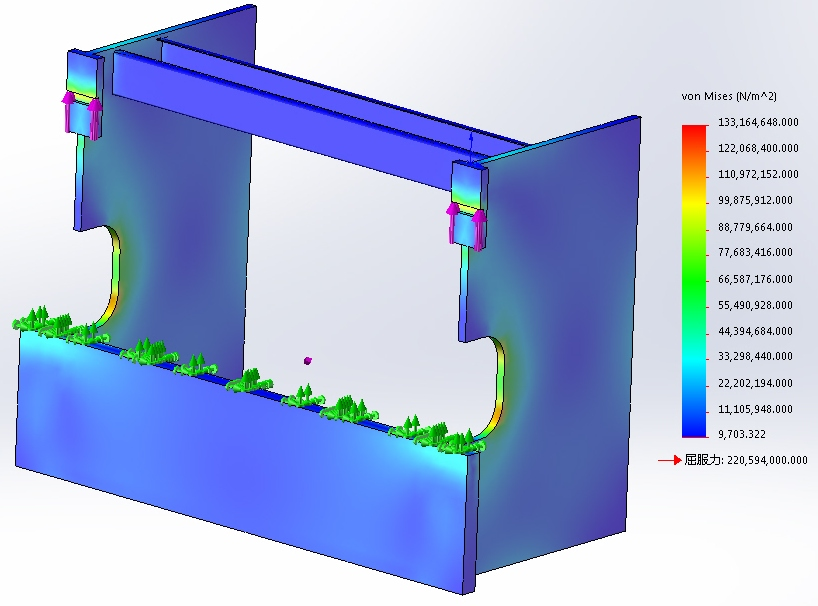

FEA & Stress Analysis

The CAE software SOLIDWORKS used to ensure reasonable frame deformation and high strength. The slider is annealed as a whole and processed as a whole with high precision, which can ensure stable precision for a long time.

|

|

|

E310P Control Unit Up to 3+1 axes (Y, X, R and V crowning) 10'' colorful touch screen Angle programming, system automatic caculate depth X and Y axis position control 220 programs, 24 steps per program English/Chinese |

|

|

SPS® Torsin Bar Structure

SPS ® NC Hydraulic Press Brake euip with the strengthen torsion shaft mechanical structure, ensure that the machine remains stable and durable after long-term use. It using high precision magnetic encoders for reliable and precision positioning.

|

|

|

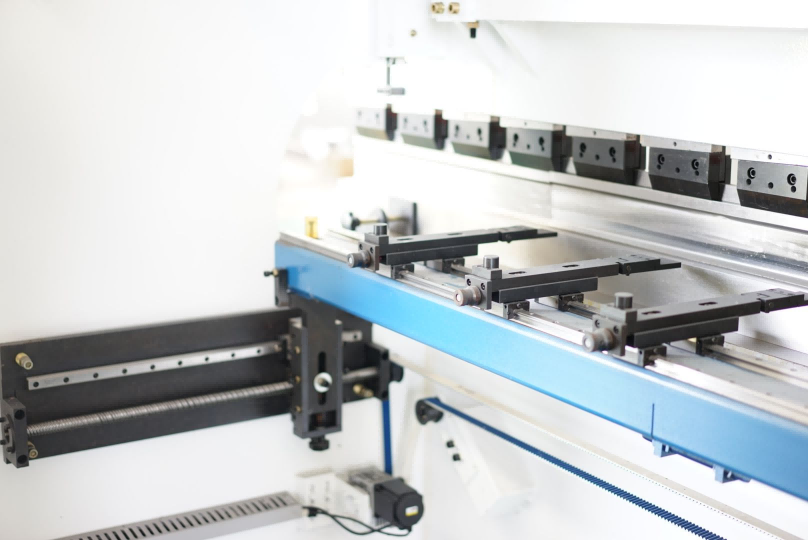

SPS® NC Press Brake Backgauge

PSA Torsion Bar Press Brake Backgauge is assembled by ball screw, linear guide rail, and movable stopper finger.

The X-axis travel is 0-600mm. There are 3 pcs of stoppers on the stopper beam, two of which can be manually moved left and right to stop the material according to different material width, and it has a manual fine-tuning structure. The back stopper beam is annealed and suitable for gantry processing center processing, with good stability and high precision.

|

|

Optional Components

|

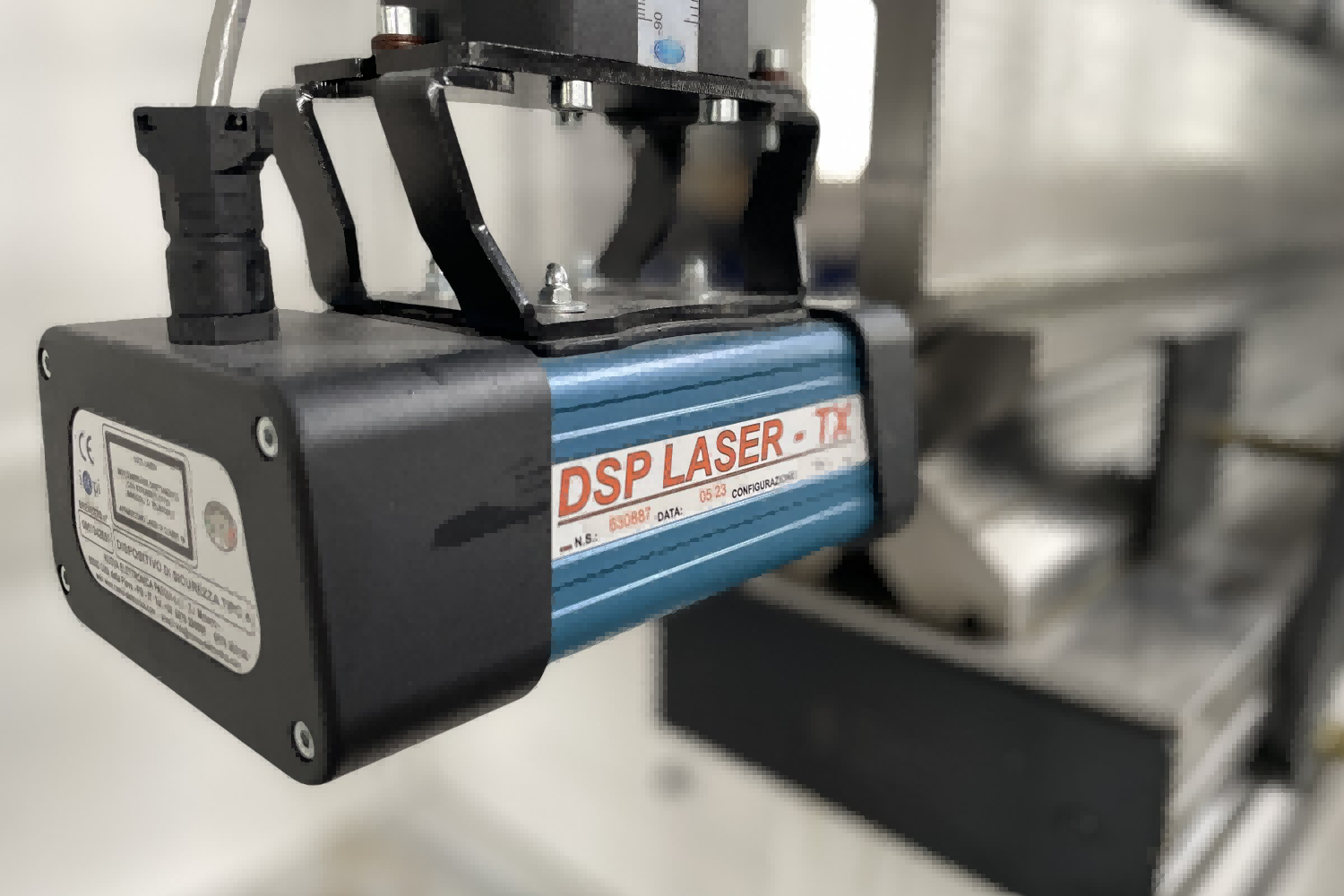

● TP10S CNC Controller ● Backgauge Servo Motor ● Italy DSP Laser Protection ● Auto Mechnical Crowing Table ● Bending Angle Measurement |

● CE Economic Light Curtain ● High Precision Multi-V Die ● WILA Hydraulic Clamping System ● WILA Tooling and Worktable System ● Auto Bending Follower Support |

|

|

|

|

|

Multi-V Die You can choose Multi V, Single V or Double V according to your workpiece demand. |

DSP Laser Protection Europe CE Standard, Protection grade IP65, Safety level reaches CAT.4 and SIL3 |

TP10 CNC Controller SPS offers a full line control system of TP10S, E310P and other controllers according to your preference. |

Easy Fast Clamping We supply Wila, Amada and Double Side Fast Claming System. |

Technical Parameters

Model |

Bending Pressure |

Bending Length |

Polo Distance |

Throat Depth |

Slide Strokes |

Max Open Height |

Backgauge Travel |

Main Motor |

Dimension |

Kn |

Mm |

Mm |

Mm |

Mm |

Mm |

Mm |

Kw |

Mm |

|

PSN-63T2500 |

630 |

2500 |

2000 |

350 |

150 |

320 |

600 |

5.5 |

2700*1340*2000 |

PSN-80T2500 |

800 |

2500 |

2000 |

350 |

150 |

460 |

600 |

5.5 |

2800*1450*2450 |

PSN-100T3200 |

1000 |

3200 |

2700 |

400 |

200 |

480 |

600 |

7.5 |

3800*1800*2650 |

PSN-100T4000 |

1000 |

4000 |

3500 |

400 |

200 |

480 |

600 |

11 |

4600*1800*2650 |

PSN-125T3200 |

1250 |

3200 |

2700 |

400 |

200 |

480 |

600 |

11 |

3800*1800*2700 |

PSN-125T4000 |

1250 |

4000 |

3500 |

400 |

200 |

480 |

600 |

11 |

4600*1800*2700 |

PSN-160T3200 |

1600 |

3200 |

2700 |

450 |

200 |

480 |

600 |

15 |

3800*2050*2800 |

PSN-160T4000 |

1600 |

4000 |

3500 |

450 |

200 |

480 |

600 |

15 |

4600*2050*2800 |

PSN-200T3200 |

2000 |

3200 |

2700 |

450 |

200 |

480 |

600 |

18.5 |

3800*2100*2900 |

PSN-200T4000 |

2000 |

4000 |

3500 |

450 |

200 |

480 |

600 |

18.5 |

4600*2100*2900 |

PSN-200T5000 |

2000 |

5000 |

3900 |

450 |

200 |

540 |

600 |

18.5 |

5600*2100*2900 |

PSN-250T3200 |

2000 |

3200 |

2700 |

450 |

250 |

540 |

600 |

18.5 |

3500*2200*2900 |

PSN-250T4000 |

2500 |

4000 |

3500 |

450 |

250 |

540 |

600 |

22 |

4300*2200*2900 |

PSN-250T5000 |

2500 |

6000 |

4900 |

450 |

250 |

540 |

600 |

22 |

5400*2200*3100 |

PSN-300T3200 |

3000 |

3200 |

2700 |

500 |

250 |

570 |

600 |

22 |

3500*2200*3200 |

PSN-300T4000 |

3000 |

4000 |

3500 |

500 |

250 |

570 |

600 |

22 |

4300*2500*3400 |

PSN-300T5000 |

3000 |

5000 |

3900 |

500 |

250 |

570 |

600 |

22 |

5400*2500*3400 |

PSN-400T3200 |

4000 |

3200 |

2700 |

500 |

300 |

570 |

600 |

30 |

3500*2700*3500 |

PSN-400T4000 |

4000 |

4000 |

3500 |

500 |

300 |

610 |

600 |

30 |

4300*2700*3500 |

PSN-400T5000 |

4000 |

5000 |

3900 |

500 |

300 |

610 |

600 |

30 |

5400*2700*3500 |

PSN-500T4000 |

5000 |

4000 |

3500 |

500 |

320 |

610 |

600 |

37 |

4300*2700*3500 |

PSN-500T5000 |

5000 |

5000 |

3900 |

500 |

320 |

610 |

600 |

37 |

5400*2700*3500 |

PSN-500T6000 |

5000 |

6000 |

4900 |

500 |

320 |

610 |

600 |

37 |

6400*2700*3600 |

PSN-600T5000 |

6000 |

5000 |

3900 |

500 |

320 |

610 |

600 |

45 |

5400*3300*3900 |

PSN-600T6000 |

6000 |

6000 |

4900 |

500 |

320 |

610 |

600 |

45 |

6400*3300*3900 |