automatic rebar bending machine

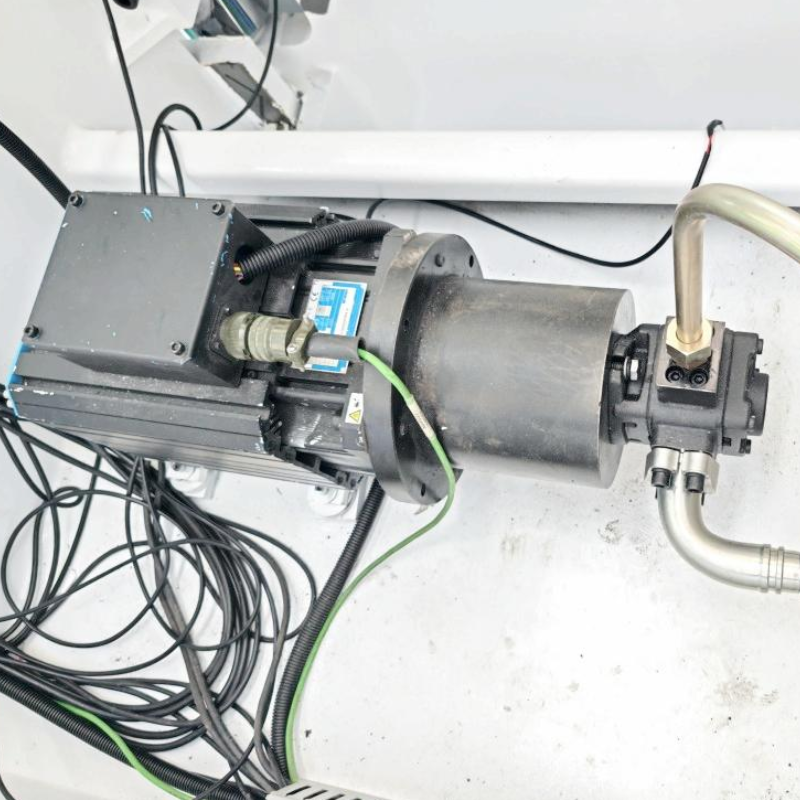

The automatic rebar bending machine represents a significant advancement in construction technology, offering precise and efficient steel reinforcement processing. This sophisticated equipment automates the complex process of bending reinforcement bars into various shapes and angles required for construction projects. The machine features a user-friendly interface that allows operators to input specific measurements and angles, ensuring consistent and accurate bends every time. Its advanced servo motor system provides precise control over bending angles, ranging from 0 to 180 degrees, while maintaining tight tolerances. The machine can handle multiple rebar sizes, typically ranging from 4mm to 40mm in diameter, making it versatile for different construction requirements. Built-in memory functions allow for storing frequently used bending patterns, significantly reducing setup time for recurring tasks. The automatic feeding system eliminates manual handling, increasing both safety and productivity. Most models incorporate digital displays and touchscreen controls for easy operation and real-time monitoring of the bending process. The machine's robust construction ensures durability and reliable performance even under heavy workloads, while its safety features, including emergency stop buttons and protective guards, guarantee operator protection during operation.