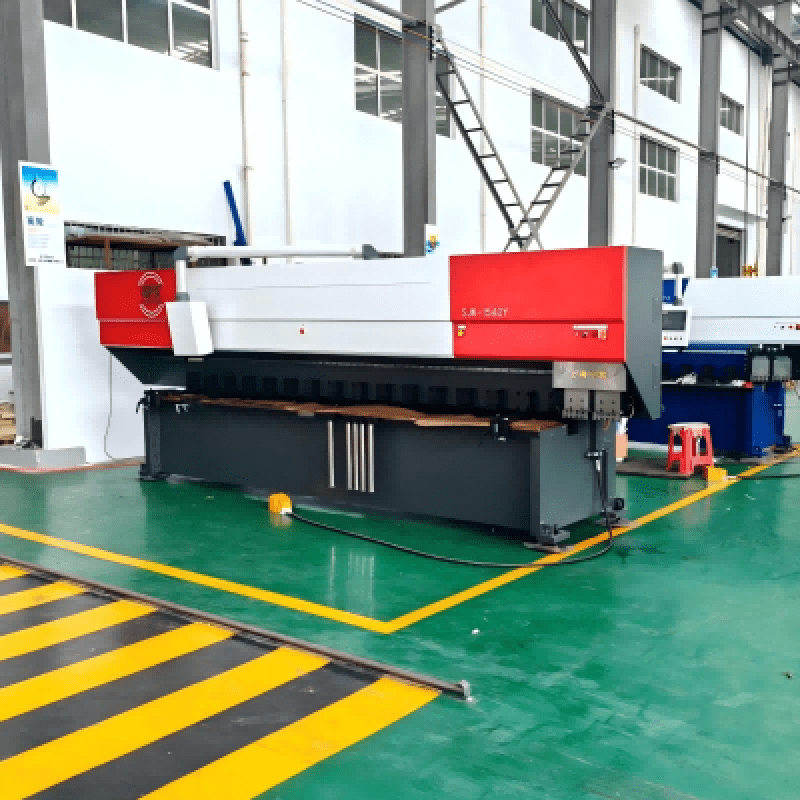

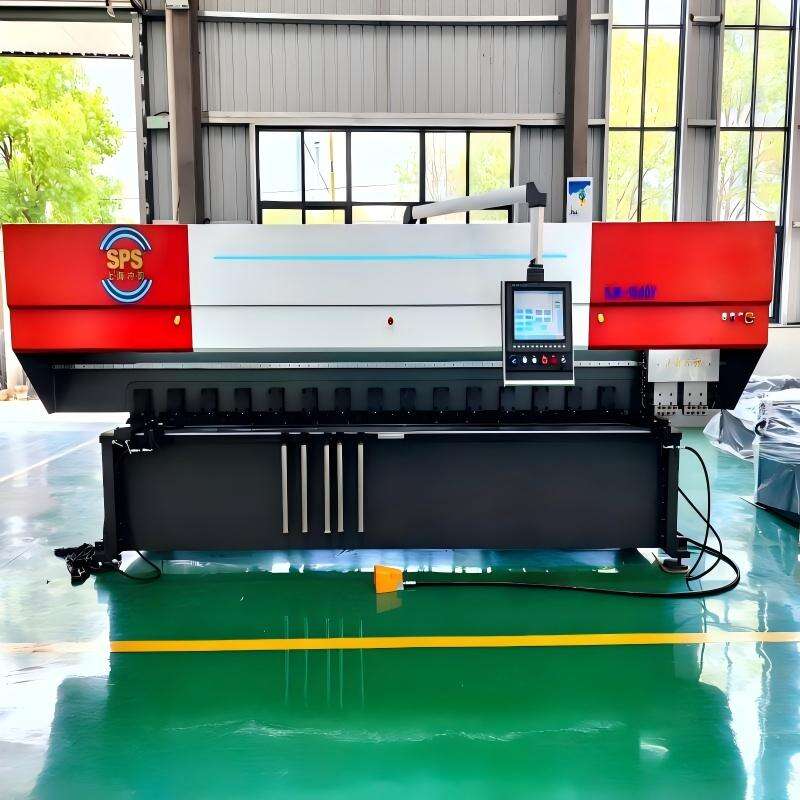

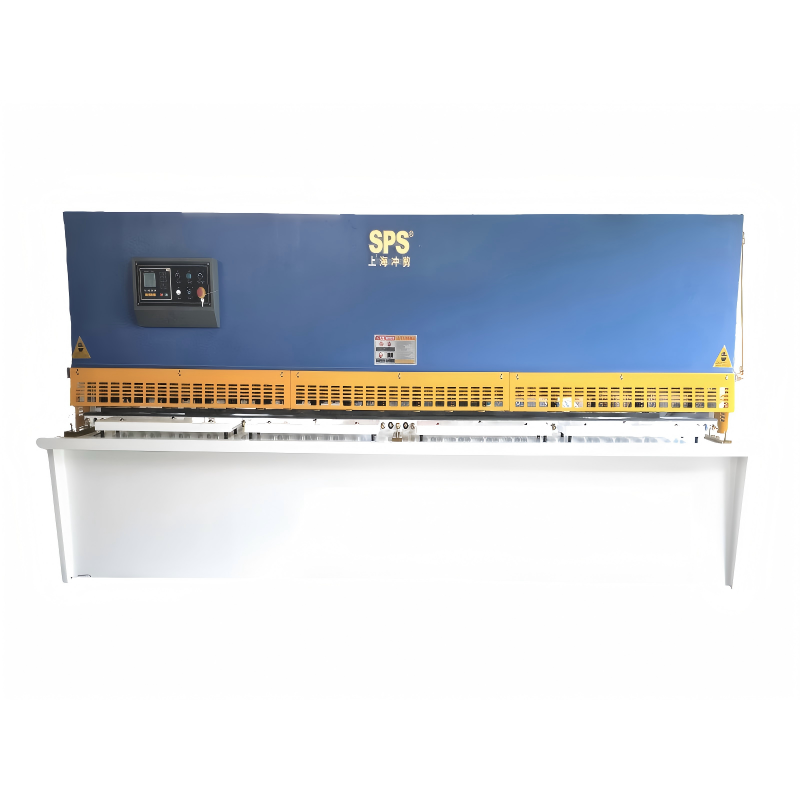

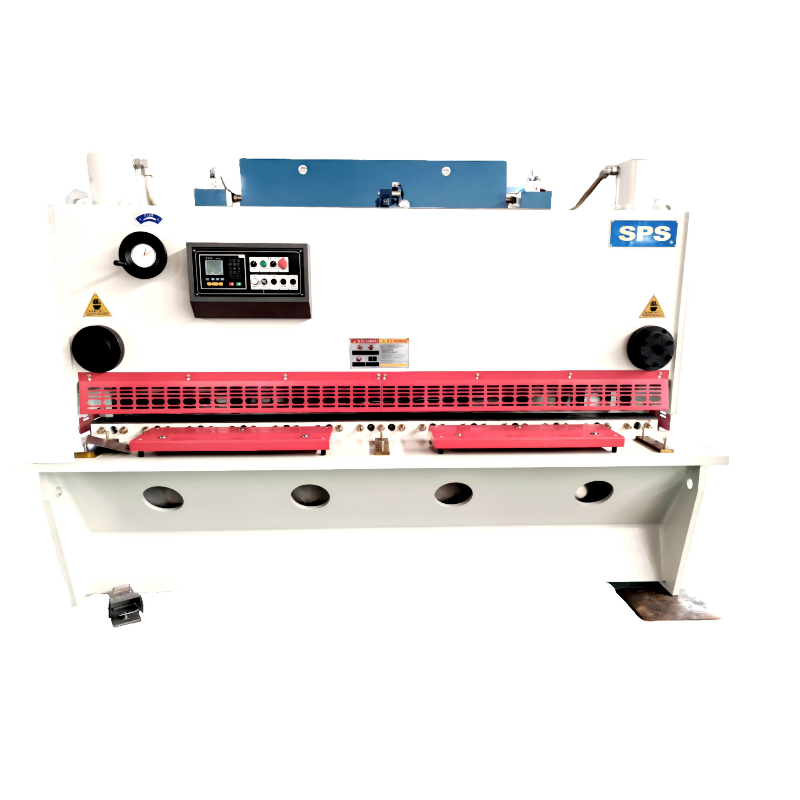

Vertical Grooving Machine-Red and white

SPS Vertical CNC V Grooving Machine is a professional slotting equipment, suitable for all metal plates, stainless steel plates, copper plates, aluminum plates, galvanized plates, etc..

- Overview

- Related Products

SPS Vertical CNC V Grooving Machine is a professional slotting equipment, suitable for all metal plates, stainless steel plates, copper plates, aluminum plates, galvanized plates, etc., particleing is an auxiliary process of plate bending and forming, in the plate needs to be bent and formed at the bending line using special equipment tools to cut out the V-shaped groove, so that the material is easy to bend and form and the bending angle R can be very small, and then use a bending machine or manual bending to form, in this way to complete the processing and meet the requirements of product appearance. The depth, width, and angle of the V-groove can be determined by the amount of feed and the shape of the planer knife during the planing process.

Standard Components

|

● Taiwan Hust CNC Controller |

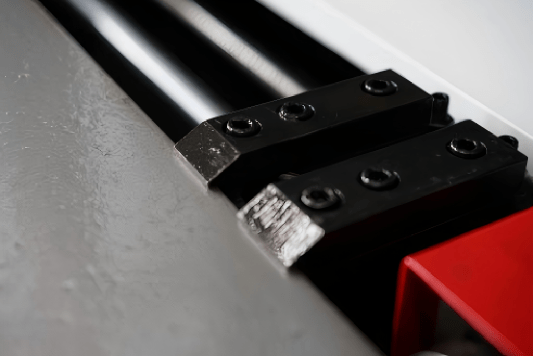

● Taiwan HIWIN Ball Screw and Linear Guide Rail |

|

● Japan Panasonic Servo Motor |

● Taiwan YYC Gear Rack Device |

|

● France Schneider Electrics |

● Japan NSK Ball Bearing |

|

● Japan Yuken Hydraulic Valve |

● Japan Valqua Sealings |

|

● Korea Korloy or Alloy Steel Blades |

● Auto Lubrication System |

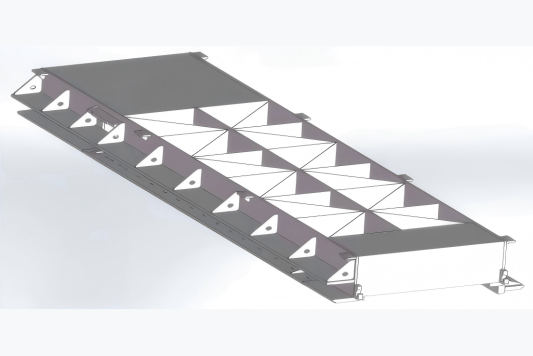

Machine Frame

SPS stainelss steel cnc v grooving machine's fuselage and crossbeam adopt an integral welded frame, and the whole machine is annealed to ensure long-term use without deformation.

The fuselage and crossbeam are processed by a gantry machining center and clamped at one time to ensure superb precision, better operating stability and longer service life..

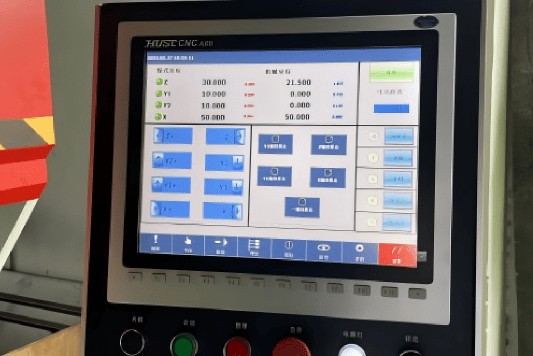

Taiwan Hust CNC Controller

SPS horizontal sheet metal v grooving machine adopt Taiwan Hust cnc controller, 15 inch intelligent touch screen, 2D graphic programming and simulation, automaticlly caculate inner and outer diameter, fixed point grooving, USB external interface.

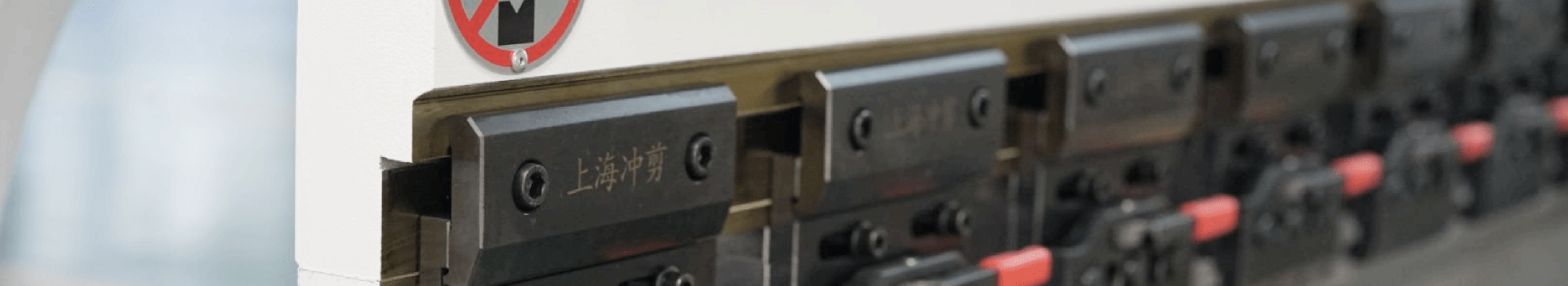

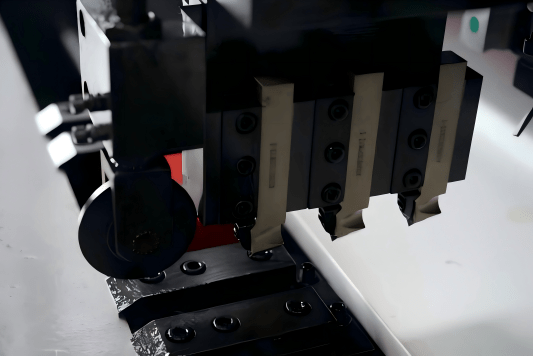

Alloy Blades

The tool holder adopts a V-groove sliding gap adjustable structure, made of ductile iron casting, with high strength, high wear resistance and better guiding performance.

• 8 Pcs of South Korea Korloy alloy blades

• Optional 4 Pcs of white steel blades with different height

• High cutting efficiency, longer blade life

• Low deformation

Hust Servo Motor and Driver

• Taiwan Hust or servo motor and driver

• Ensuring long-term reliability and stability.

More details of cnc v groover machine

Taiwan HIWIN Linear Guide

Hydraulic Pressing System

Movable Clamping System

Schneider Electris

Technical Parameters

|

Model |

Unit |

SJK12532Y |

SJK12540Y |

SJK1532Y |

SJK1540Y |

SJK1560Y |

|

Max Cutting Width(Y axis) |

Mm |

1250 |

1250 |

1500 |

1500 |

1500 |

|

Max Cutting Length (X axis) |

Mm |

3200 |

4000 |

3200 |

4000 |

6000 |

|

Tool Holder Travel ( Z axis) |

Mm |

60 |

60 |

60 |

60 |

60 |

|

Cutting Thickness |

Mm |

0.45-6 |

0.45-6 |

0.45-6 |

0.45-6 |

0.45-6 |

|

Min Edge Width |

Mm |

8 |

8 |

8 |

8 |

8 |

|

Y axis |

Mm |

60 |

60 |

60 |

60 |

60 |

|

Table Flatness |

Mm |

±0.03 |

||||

|

Cutting Speed (X axis) |

M/min |

120 |

||||

|

Tool Holder Moving Speed ( Y axis) |

M/min |

40-100 |

||||

|

Tool Holder Moving Speed ( Z axis) |

M/min |

3.5 |

||||

|

Positioning Accuracy |

Mm |

±0.01 |

||||

|

X Axis Servo Main Motor |

Kw |

5.5 |

5.5 |

5.5 |

5.5 |

5.5 |

|

Hydraulic Pressure |

Mpa |

4-8 |

4-8 |

4-8 |

4-8 |

4-8 |

|

Cutting Blade Installed |

Pc |

8 |

8 |

8 |

8 |

8 |

|

Dimension |

Mm |

5500*2700*2100 |

6300*2700*2100 |

5500*3500*2200 |

6300*3500*2200 |

8300*3500*2200 |