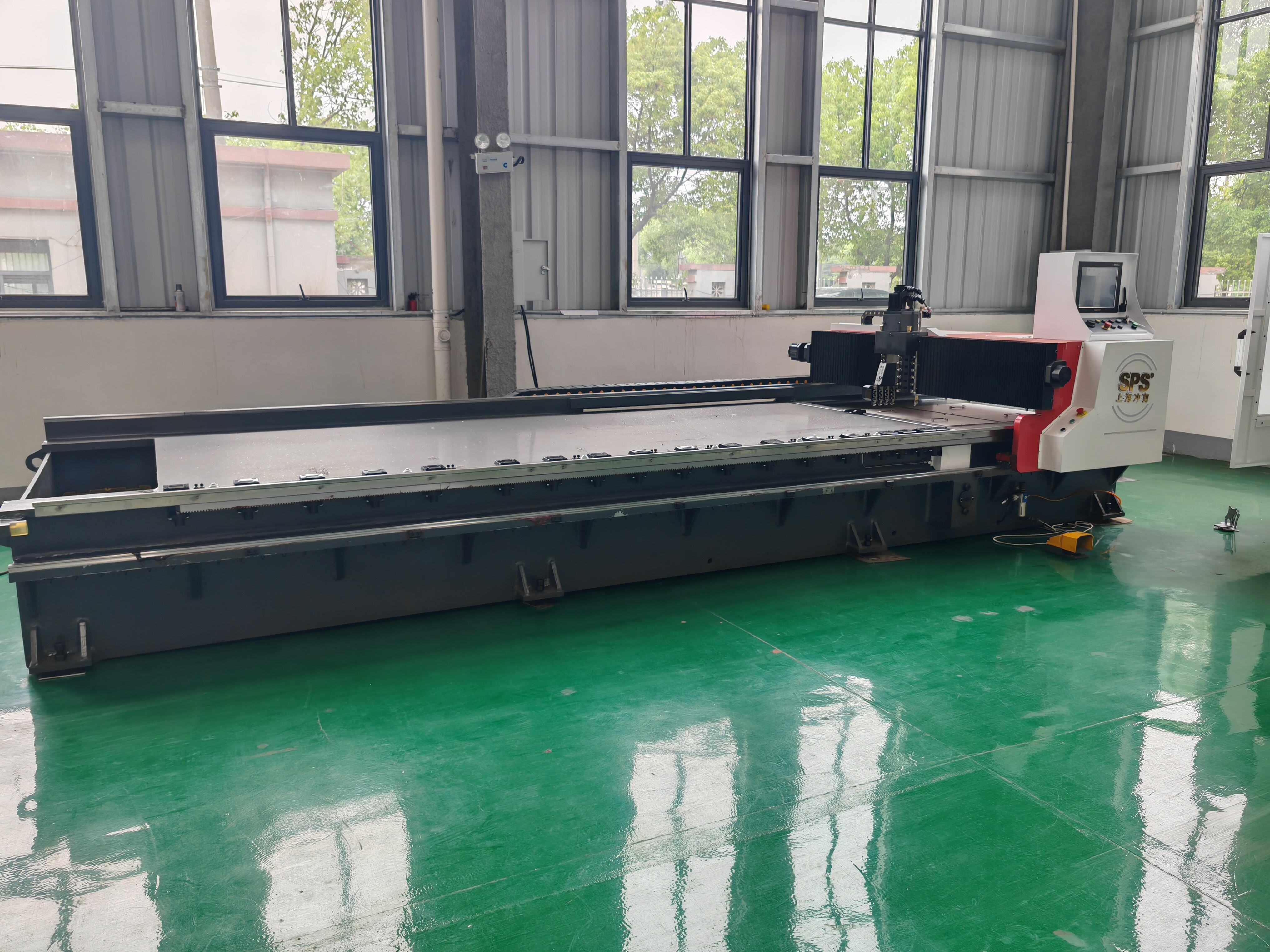

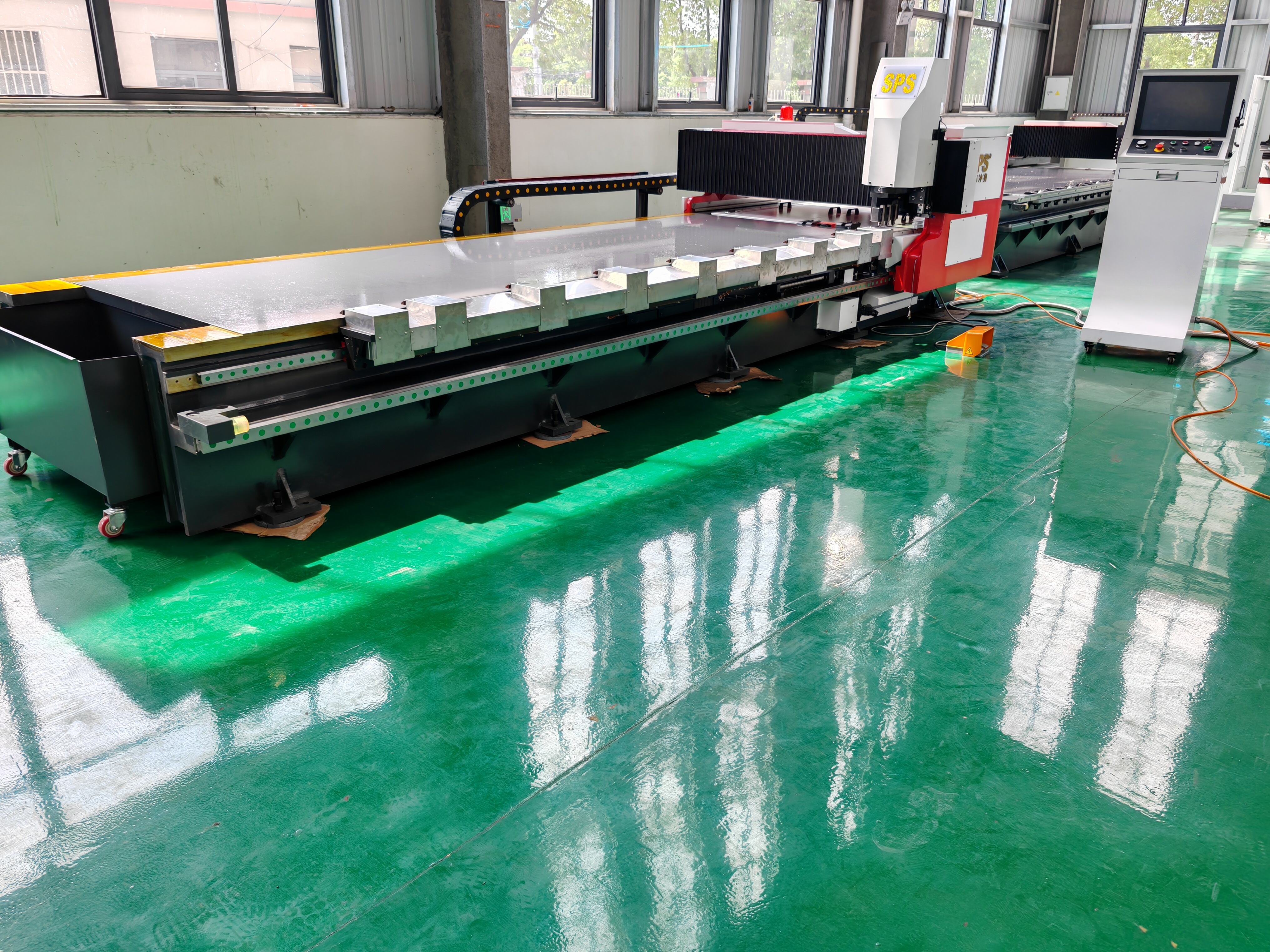

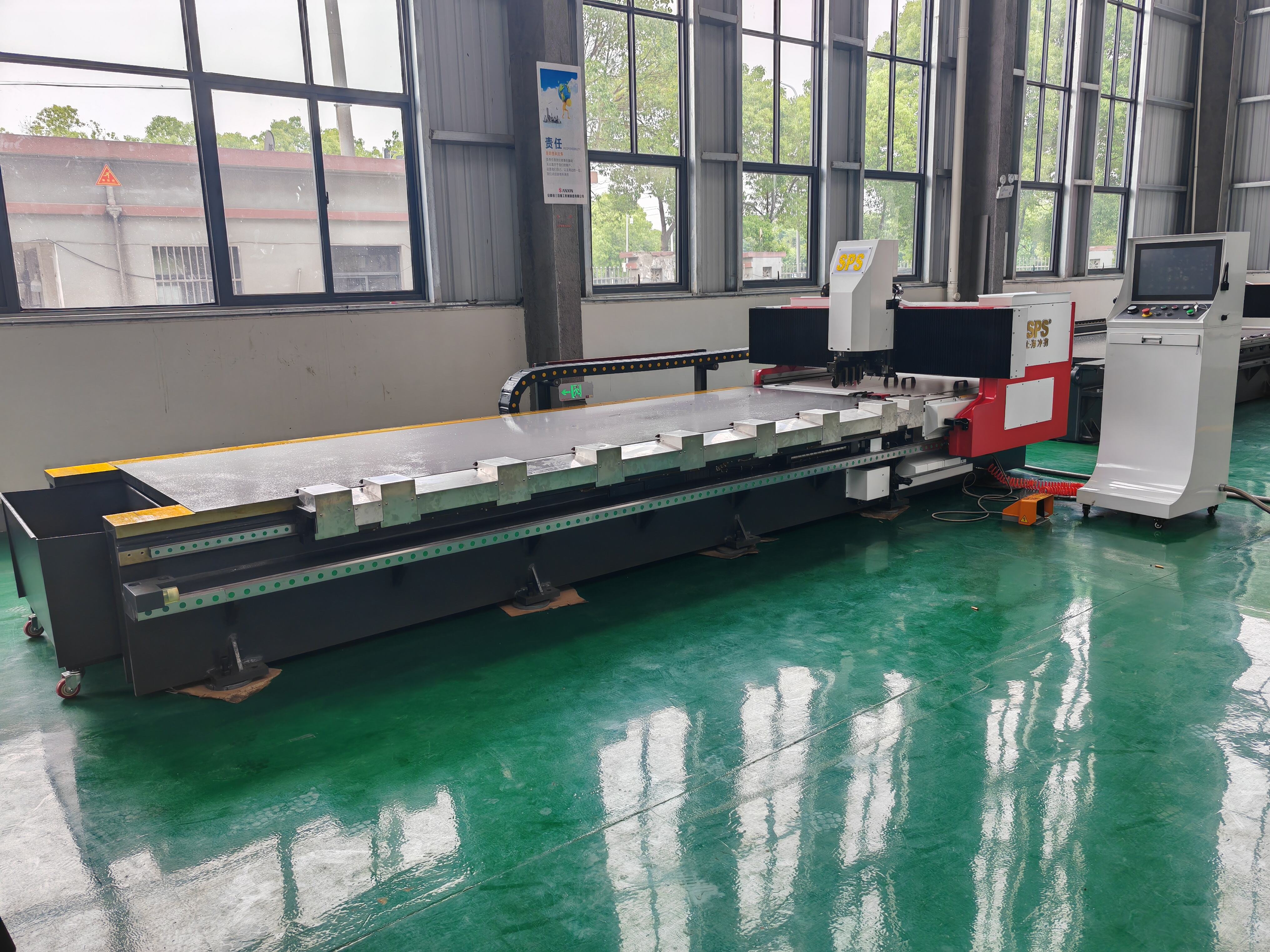

concrete core cutting machine

A concrete core cutting machine is a specialized power tool designed for precise cutting and drilling through concrete structures. This advanced equipment utilizes diamond-tipped blades or bits to create clean, accurate holes and cuts in reinforced concrete, masonry, and other hard materials. The machine operates through a combination of rotary motion and controlled pressure, allowing for precise depth control and straight cutting paths. Modern concrete core cutting machines feature water cooling systems that suppress dust, extend blade life, and maintain cutting efficiency. These machines are available in various sizes and configurations, from handheld units for small projects to large track-mounted systems for industrial applications. The technology incorporates variable speed controls, allowing operators to adjust cutting speeds based on material density and composition. Safety features include emergency stop mechanisms, thermal protection, and ergonomic designs to reduce operator fatigue. The machines can achieve cutting depths of up to 24 inches, depending on the model, and can handle diameters ranging from less than an inch to several feet. They are essential tools in construction, renovation, and infrastructure maintenance, enabling contractors to create openings for utilities, perform structural modifications, and execute precise demolition work.