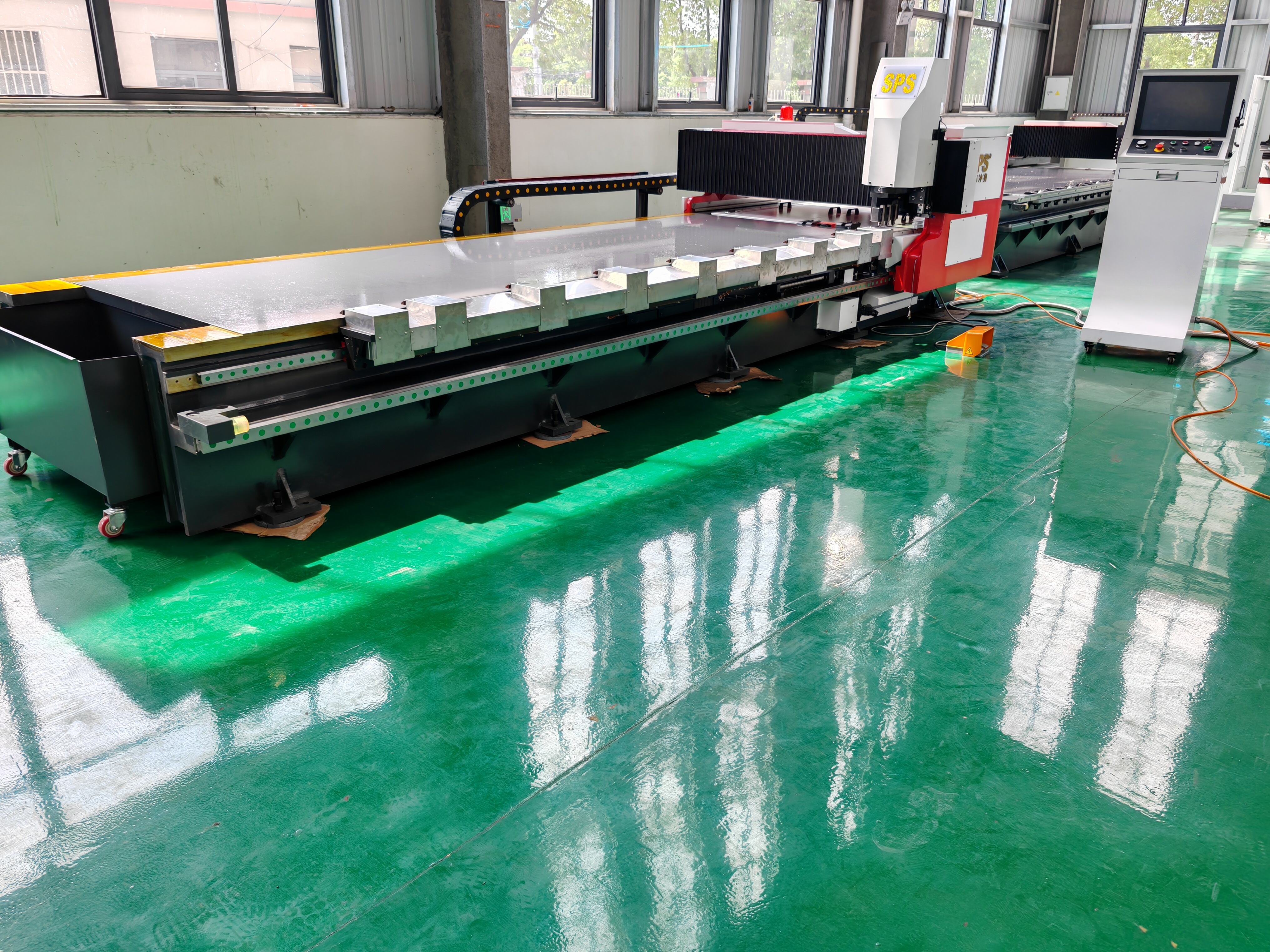

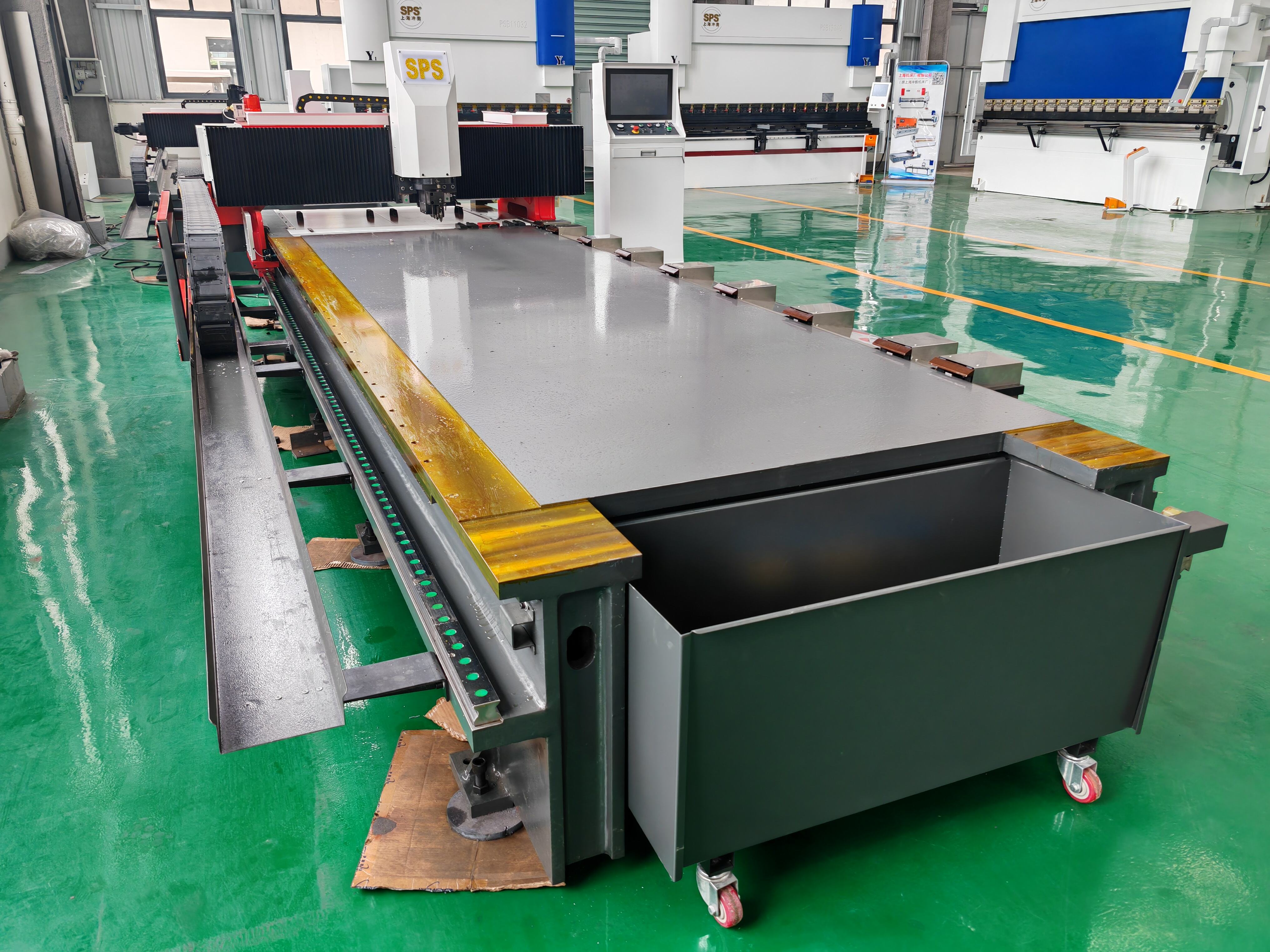

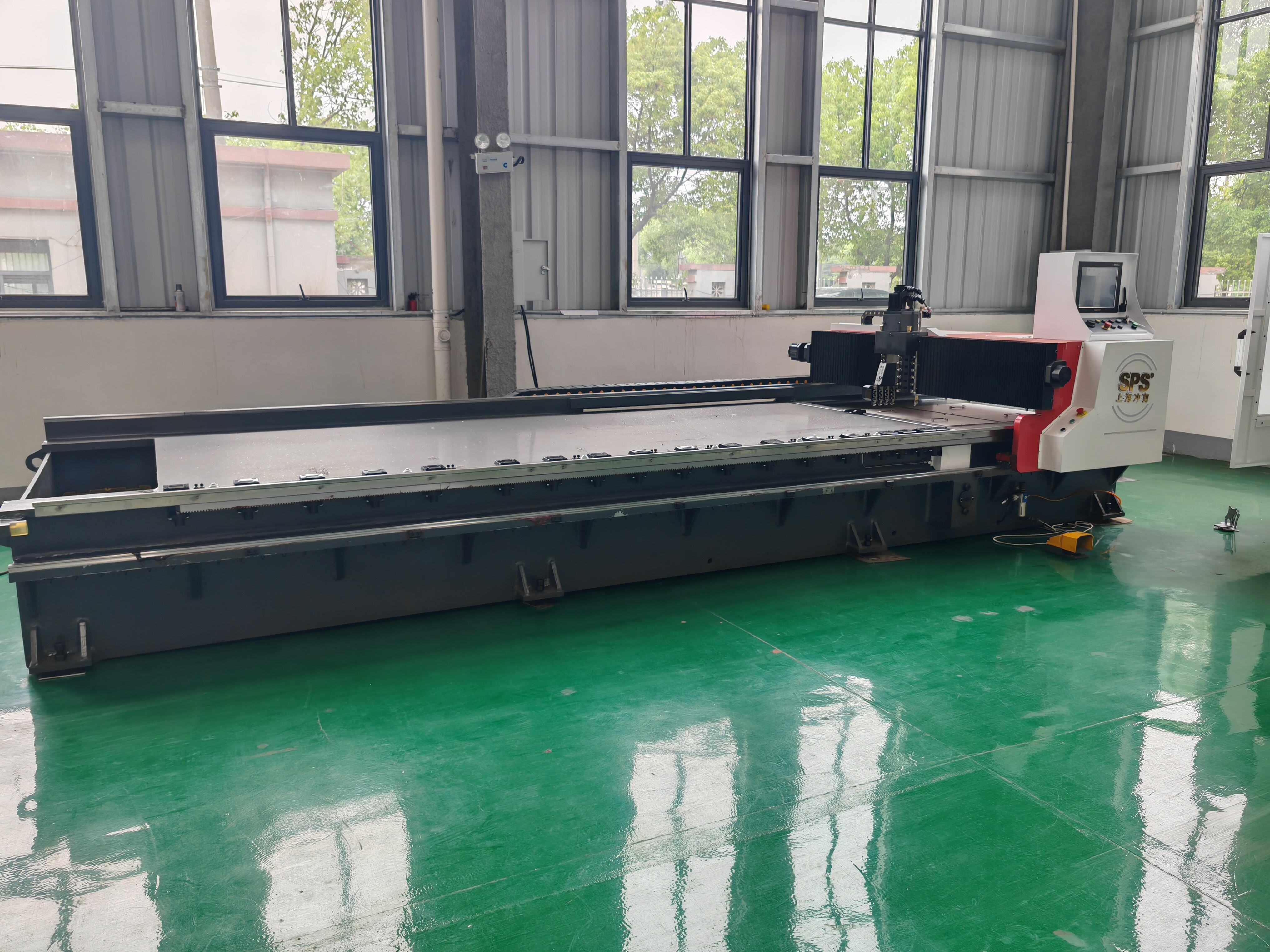

round cutting machine

A round cutting machine is a precision engineering tool designed to create accurate circular cuts in various materials. This versatile equipment combines advanced cutting technology with precise control mechanisms to deliver consistent, high-quality results. Operating through a combination of rotary motion and precise blade positioning, these machines can handle materials ranging from metal and plastic to wood and composite materials. The cutting process is controlled by sophisticated electronic systems that maintain optimal cutting speed and depth, ensuring clean edges and minimal material waste. The machine features adjustable parameters for cutting diameter, depth, and speed, allowing operators to customize settings for different materials and specifications. Modern round cutting machines often incorporate digital displays and programmable controls, enabling precise measurements and repeatable results. Safety features include emergency stop mechanisms, blade guards, and automatic shut-off systems to protect operators. The machine's robust construction ensures stability during operation, while its modular design facilitates maintenance and component replacement. Advanced models may include features like automatic material feeding, integrated cooling systems, and dust collection capabilities, making them suitable for both industrial production and specialized manufacturing applications.