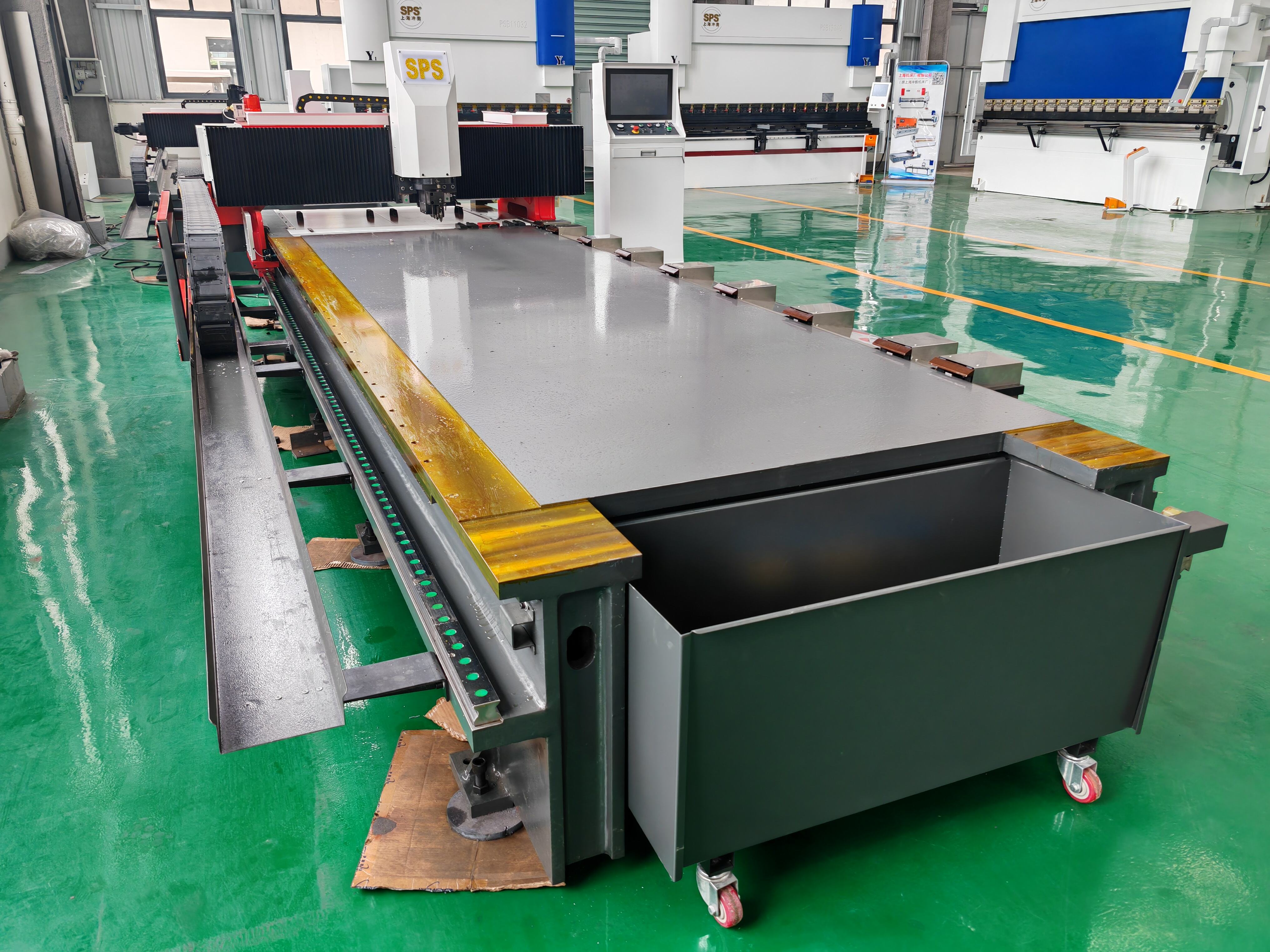

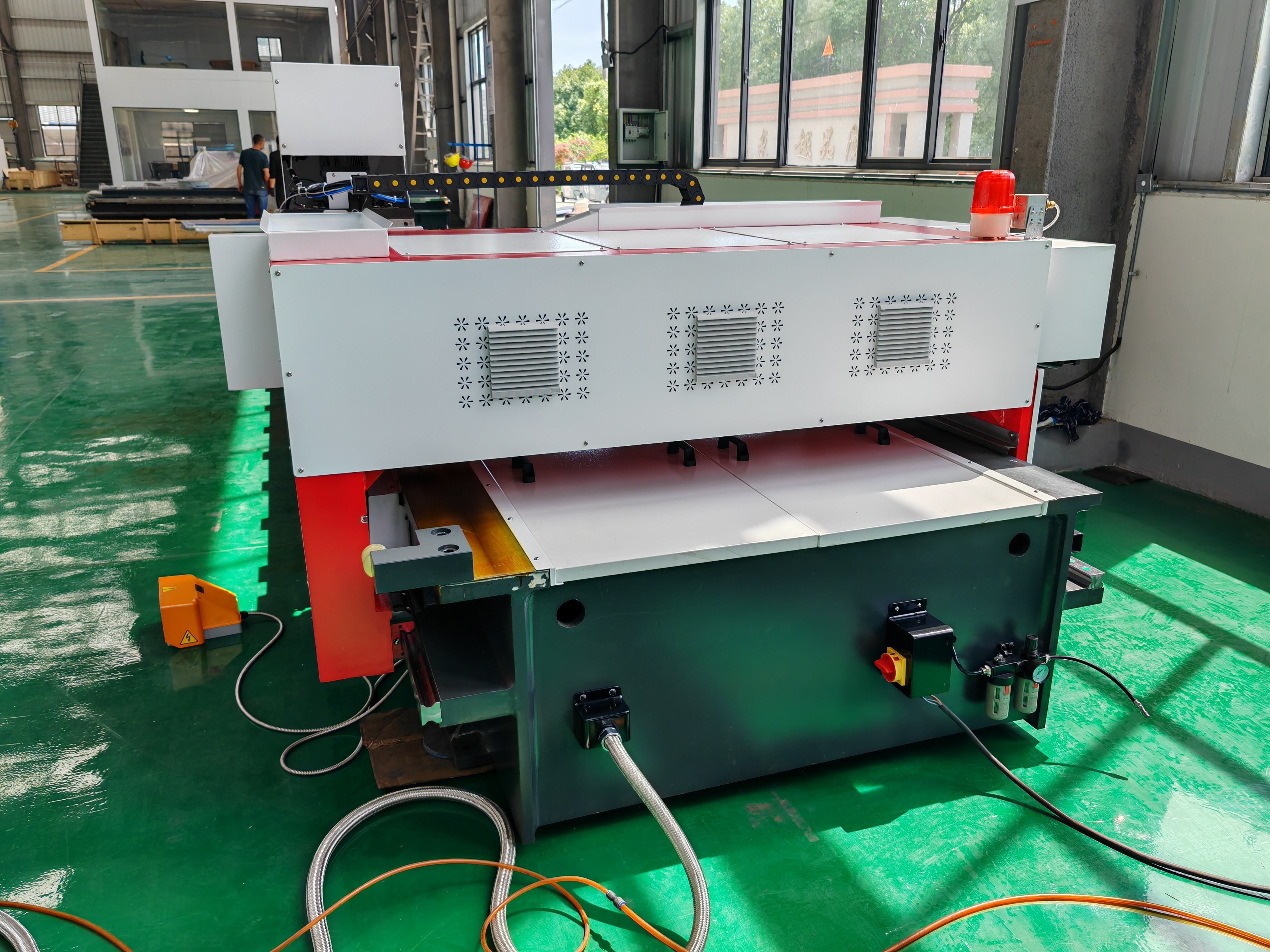

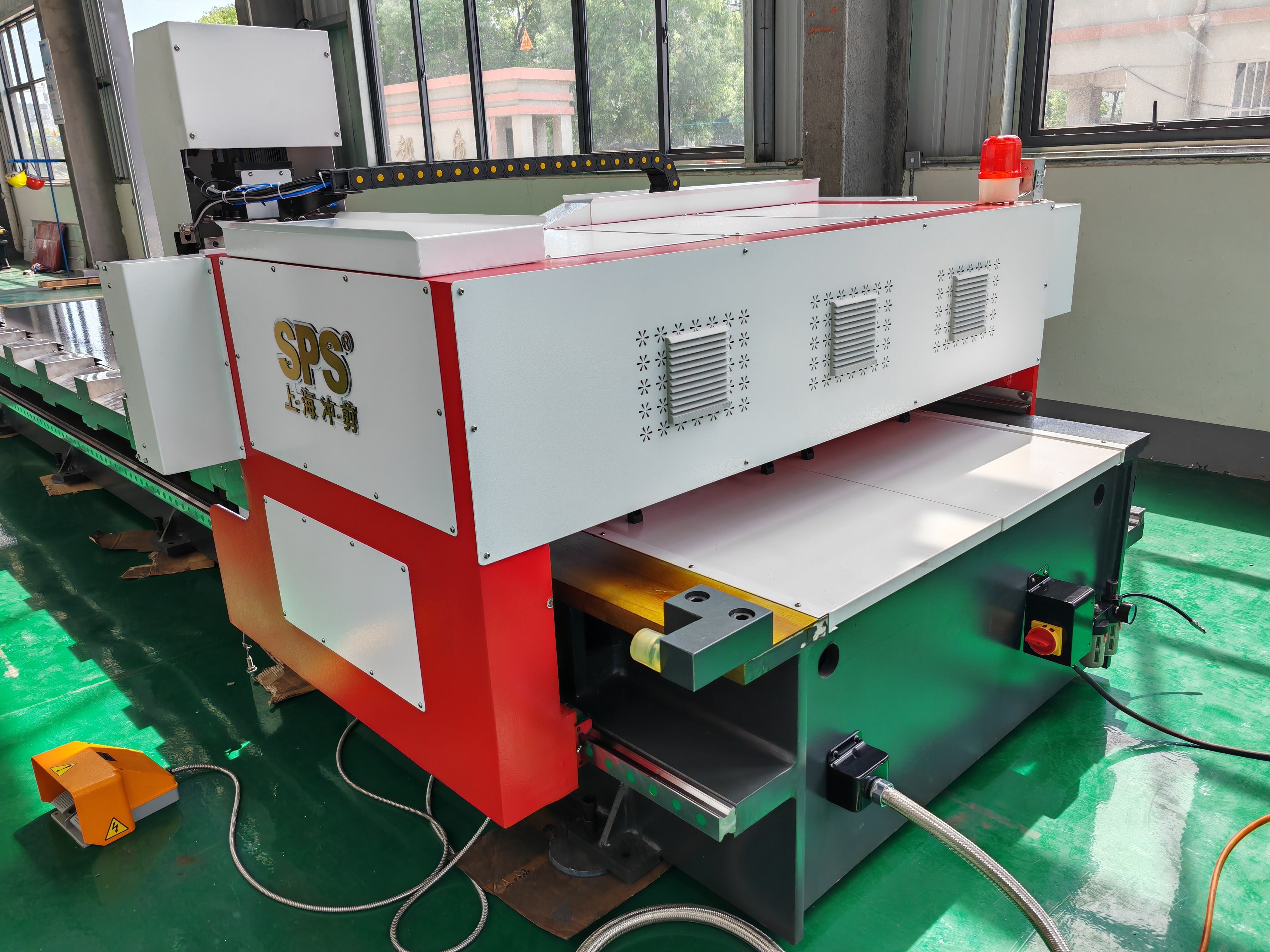

manual cutting machine

A manual cutting machine represents a fundamental yet sophisticated tool in manufacturing and crafting industries, offering precise control over cutting operations without the need for electrical power. This versatile equipment features a robust mechanical system typically comprising a sturdy base, adjustable cutting blade, measurement guides, and a manual lever or wheel mechanism for operation. The machine's design incorporates safety features including blade guards and clamps to secure materials during cutting processes. It excels in applications requiring accurate straight cuts across various materials such as paper, cardboard, plastic sheets, thin metals, and vinyl. The cutting mechanism operates through a direct transfer of force from the operator's input to the cutting blade, allowing for exceptional control over cutting pressure and speed. Most models include calibrated rulers and angle guides ensuring precise measurements and consistent results. The machine's durability comes from high-grade steel construction, with hardened cutting blades that maintain sharpness through extended use. Its adaptability to different material thicknesses and types makes it particularly valuable in print shops, manufacturing facilities, and creative workshops where versatility is essential.