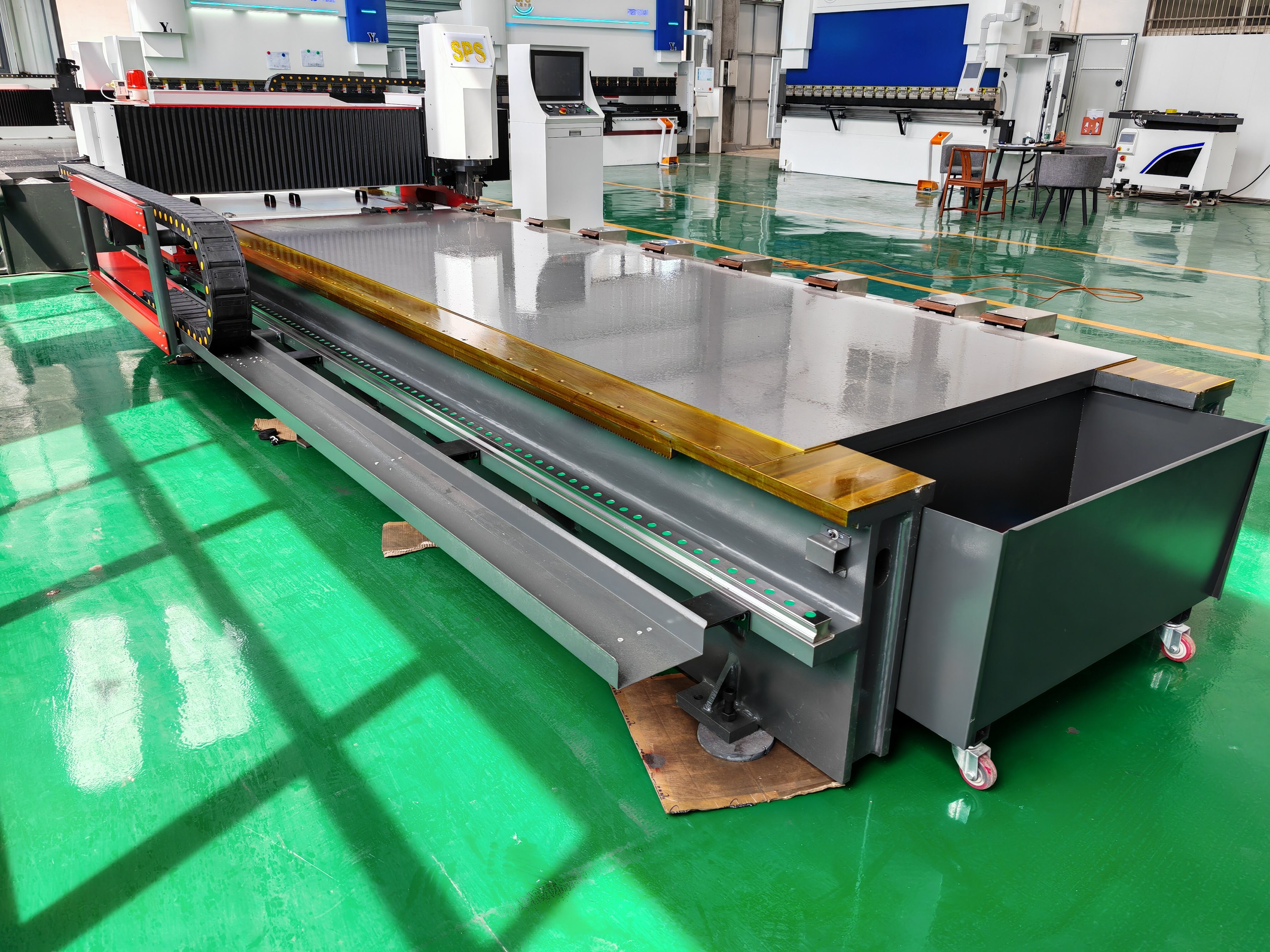

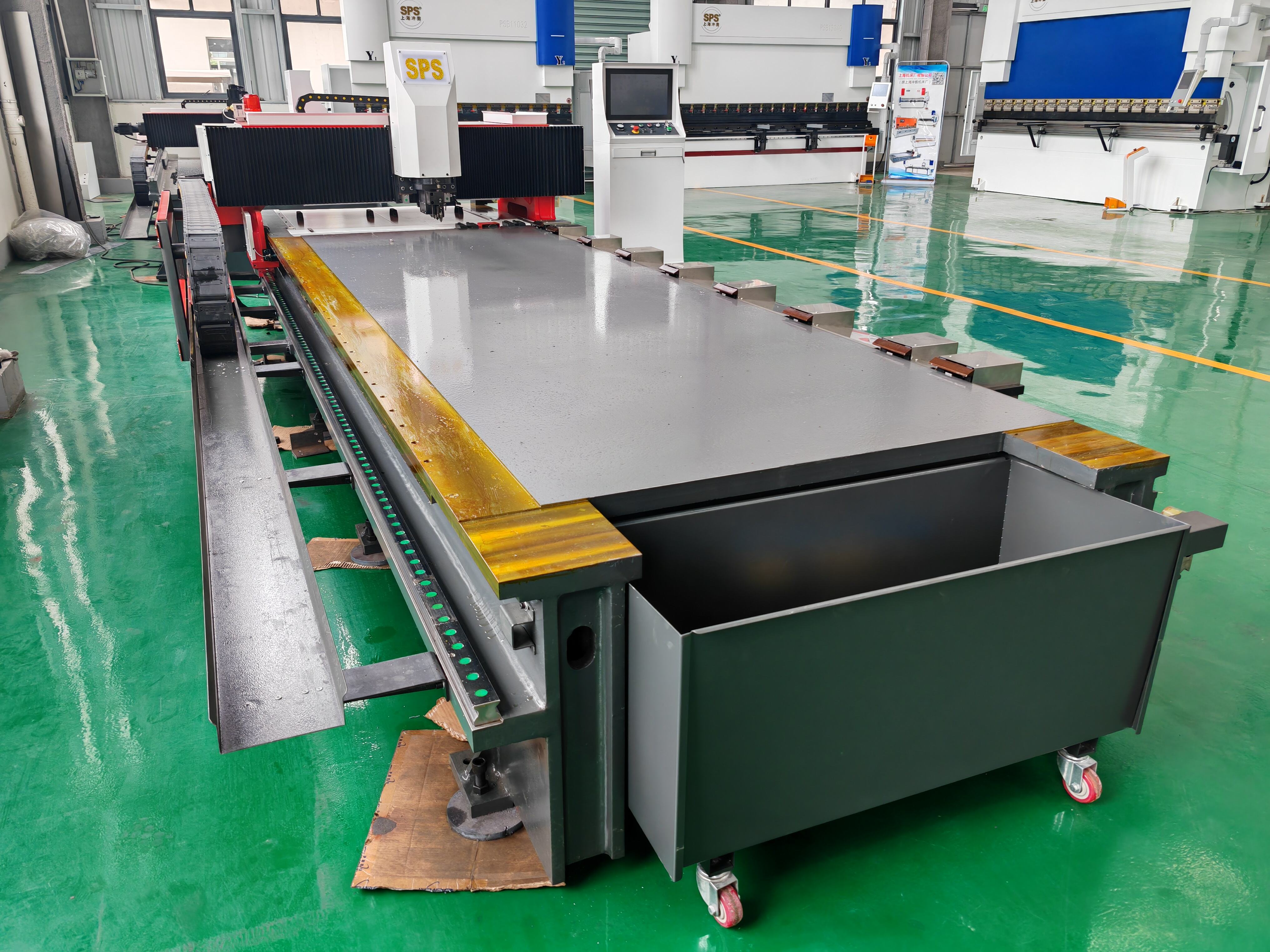

mini laser cutting machine

The mini laser cutting machine represents a revolutionary advancement in compact manufacturing technology, offering professional-grade cutting capabilities in a space-efficient design. This versatile device utilizes precise laser beam technology to cut through various materials including acrylic, wood, leather, and thin metals with exceptional accuracy. The machine features an integrated cooling system and advanced motion control technology, ensuring consistent cutting quality and extended operational life. Its user-friendly interface allows both beginners and experienced operators to achieve professional results, while the compact footprint makes it ideal for small workshops, design studios, and home-based businesses. The machine incorporates safety features such as automatic shutdown protection and enclosed cutting chamber, maintaining workplace safety standards. With adjustable power settings ranging from 40W to 60W, users can fine-tune the cutting parameters for different material thicknesses and types. The built-in positioning system ensures accurate cuts within 0.01mm precision, while the machine's compatibility with common design software platforms like CorelDraw and AutoCAD enhances its versatility in various applications, from prototype development to small-scale production runs.