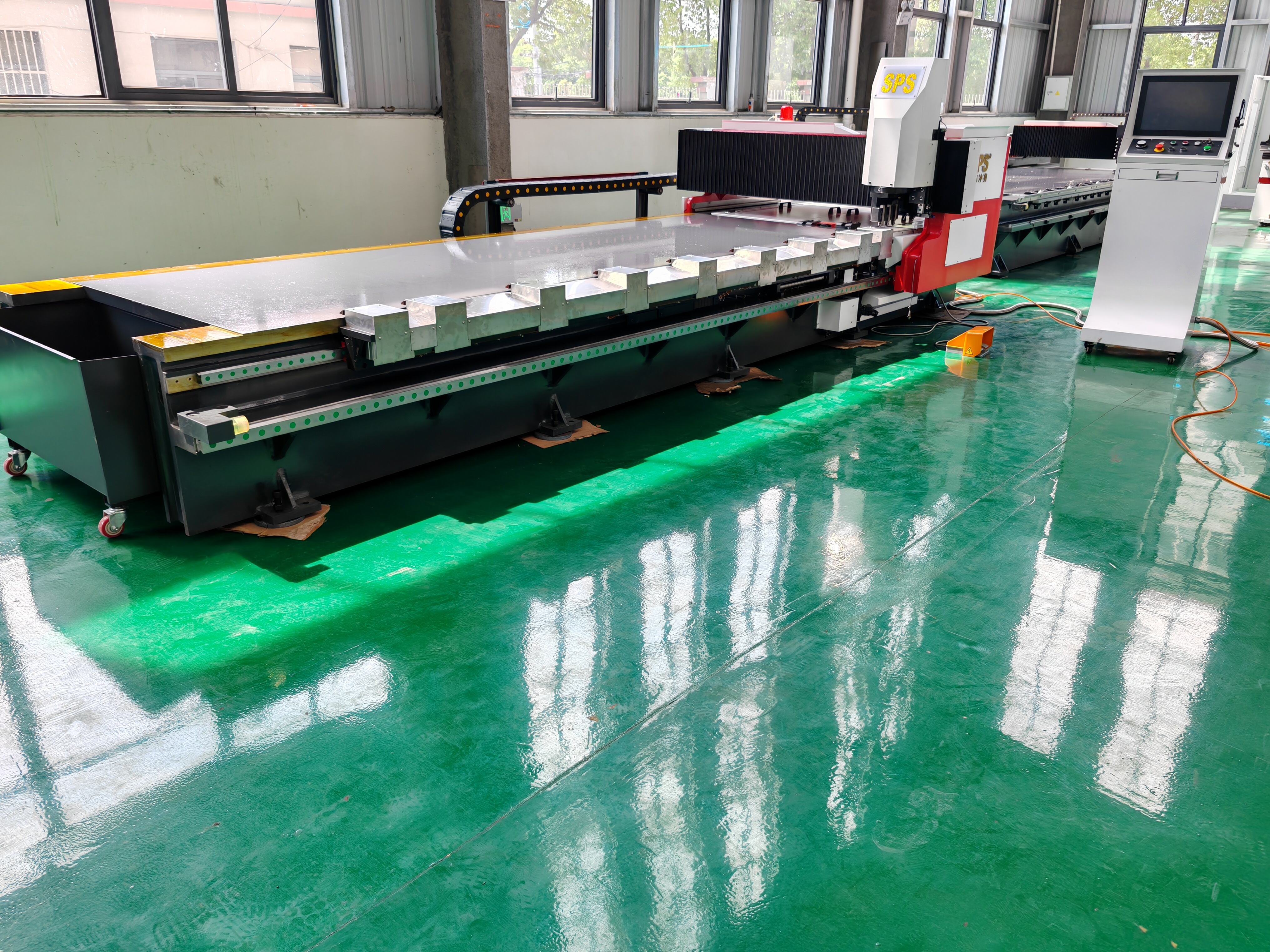

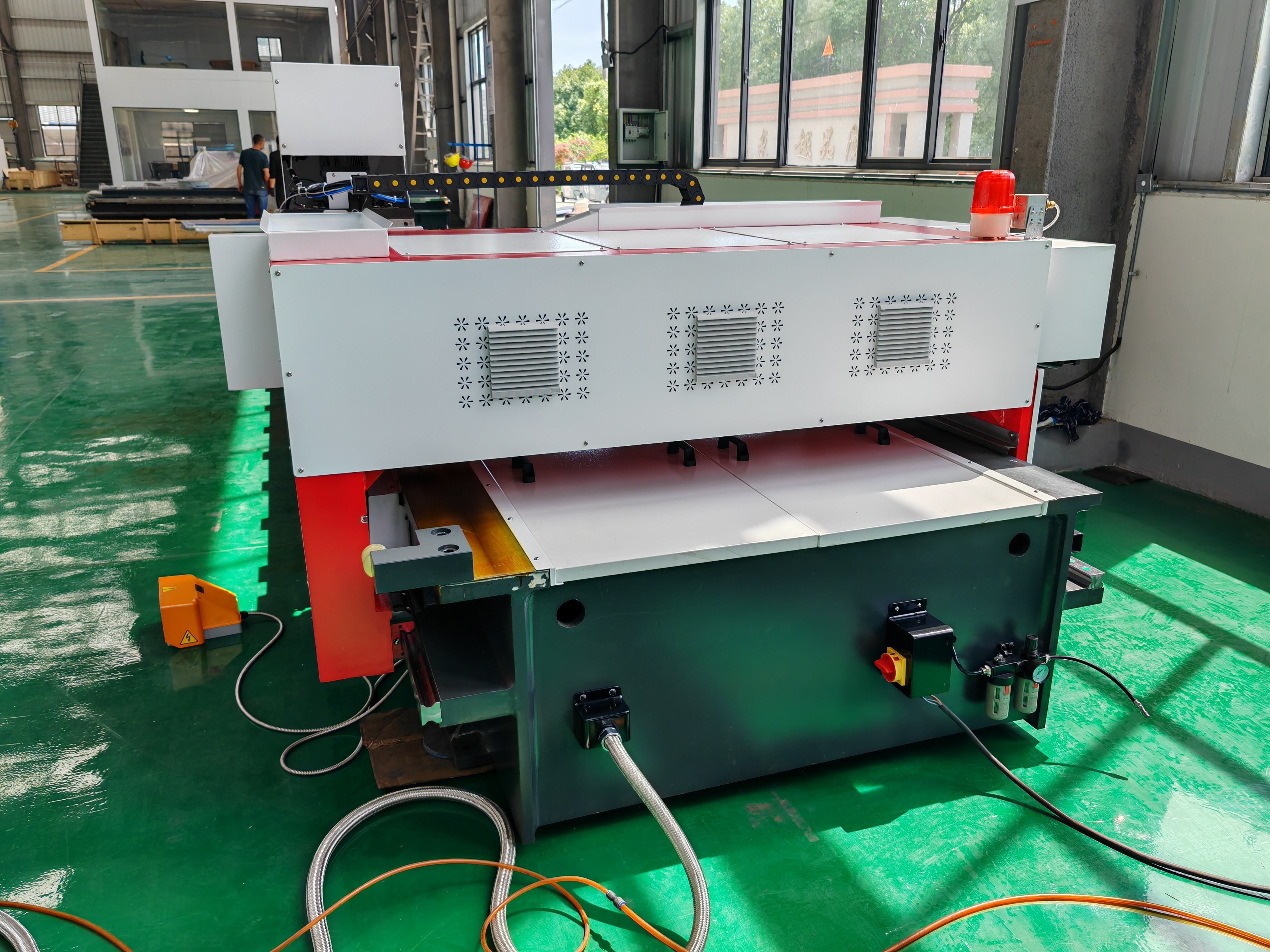

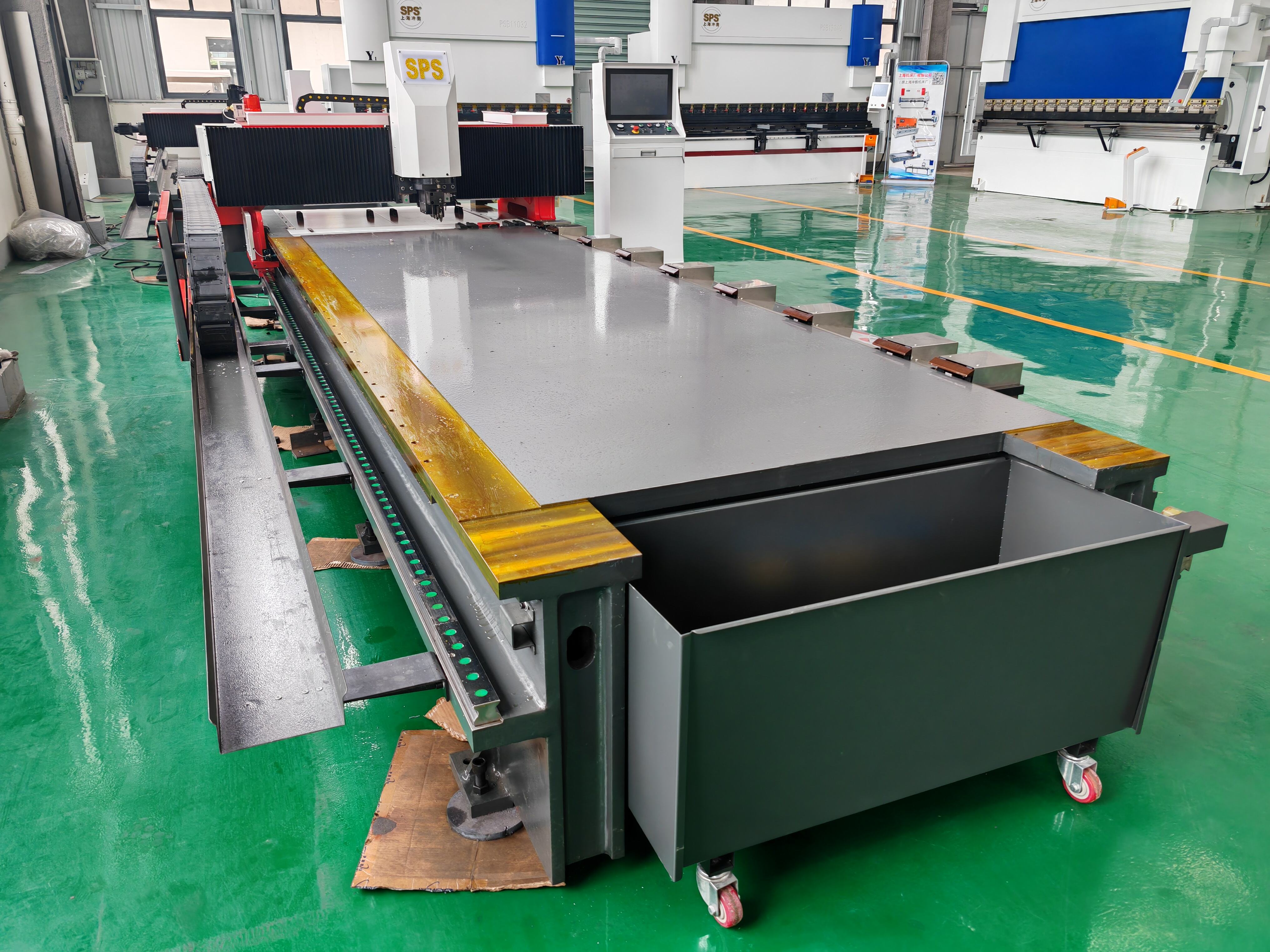

acrylic sheet cutting machine

The acrylic sheet cutting machine represents a sophisticated piece of manufacturing equipment designed specifically for precise cutting and processing of acrylic materials. This advanced system combines robust mechanical engineering with computer-controlled precision to deliver exceptional cutting results. The machine utilizes high-powered laser technology or mechanical cutting tools to process acrylic sheets of various thicknesses, typically ranging from 2mm to 30mm. Its main functions include straight cutting, curve cutting, engraving, and edge finishing, all controlled through an intuitive digital interface. The machine's technological features encompass automatic tool changing systems, precise positioning mechanisms, and advanced safety features that protect both operators and materials. The cutting process is guided by CAD/CAM software, allowing for complex designs and patterns to be executed with remarkable accuracy. Applications of the acrylic sheet cutting machine span across multiple industries, including signage manufacturing, retail display production, architectural elements, and custom fabrication. The machine's versatility makes it equally suitable for small-scale artistic projects and large-scale industrial production, offering consistent quality and reliability in every cut.