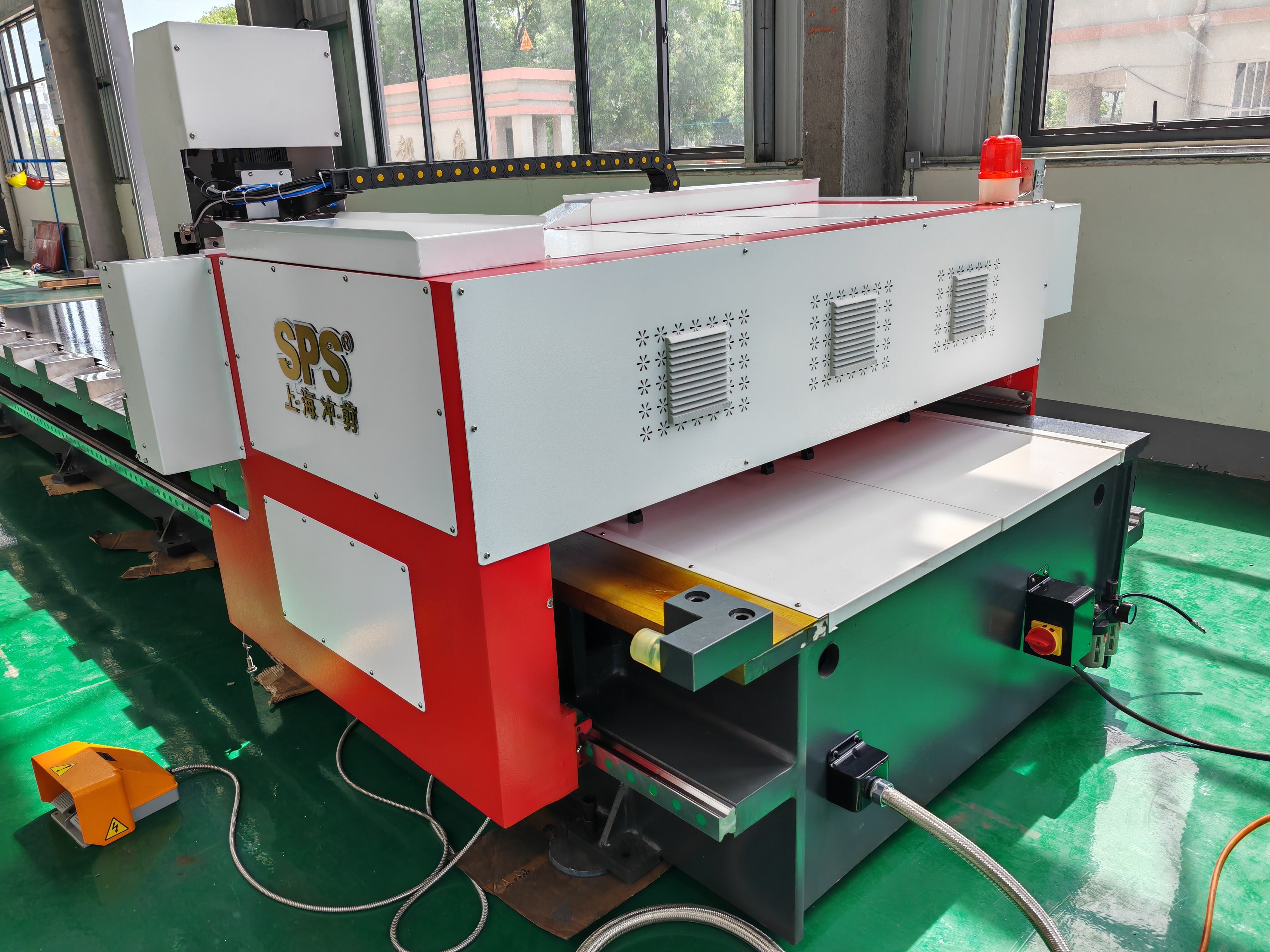

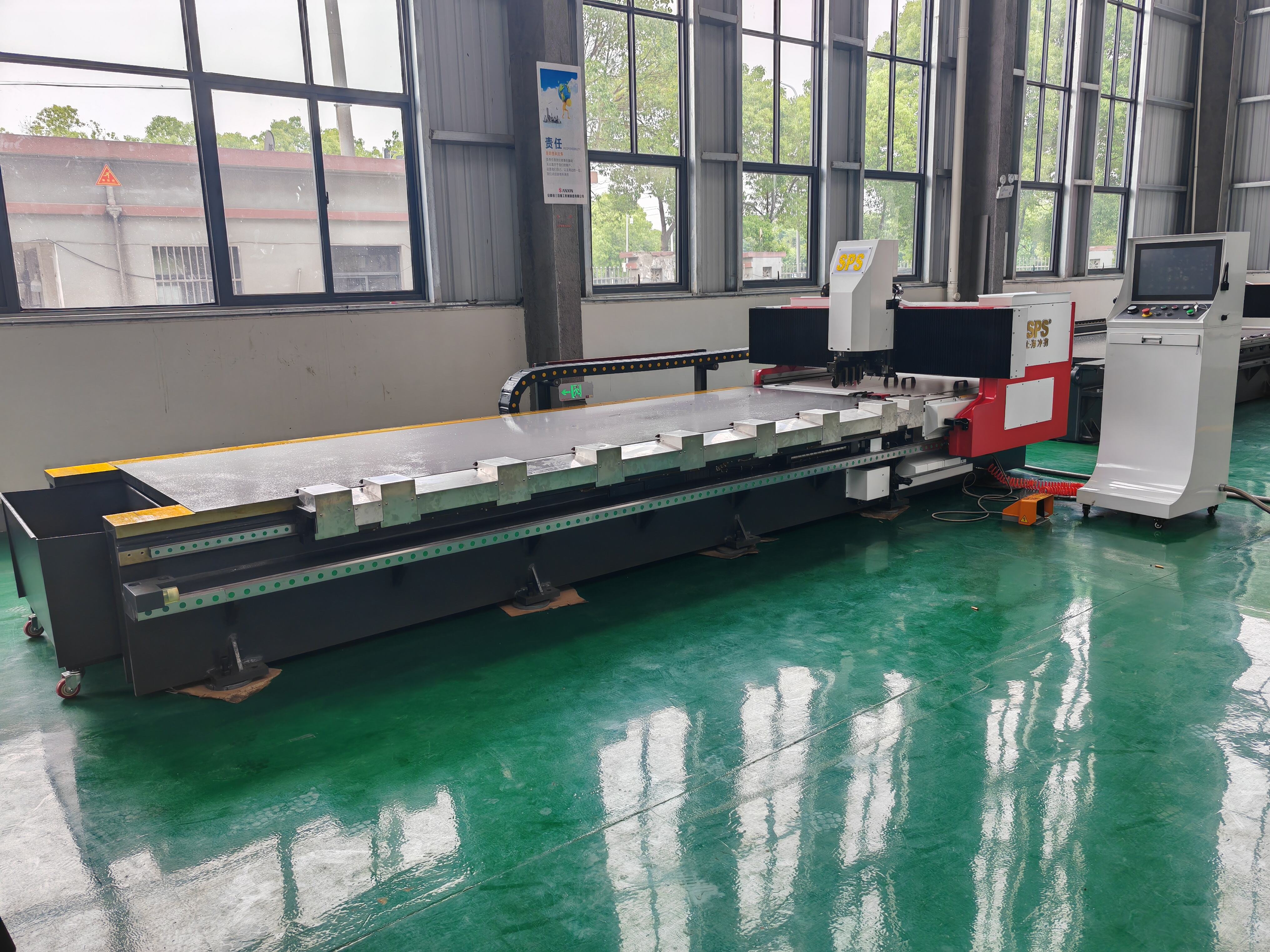

lens cutting machine

A lens cutting machine represents a pinnacle of precision engineering in optical manufacturing, designed to transform raw lens materials into perfectly crafted optical components. This sophisticated equipment employs advanced computer numerical control (CNC) technology to execute precise cuts and shapes according to exact specifications. The machine utilizes diamond cutting tools and high-speed spindles to achieve superior surface finish and accuracy down to micrometers. It can process various materials including glass, plastic, and crystal, making it versatile for different optical applications. The system incorporates real-time monitoring and automatic error compensation mechanisms to maintain consistent quality throughout the cutting process. Modern lens cutting machines feature integrated cooling systems to prevent heat-induced deformations and automated tool changing capabilities for continuous operation. They can perform multiple operations including rough cutting, fine finishing, and edge processing, all within a single setup. These machines are essential in producing lenses for eyewear, cameras, microscopes, and various scientific instruments, ensuring precise optical characteristics and geometric accuracy in every piece produced.