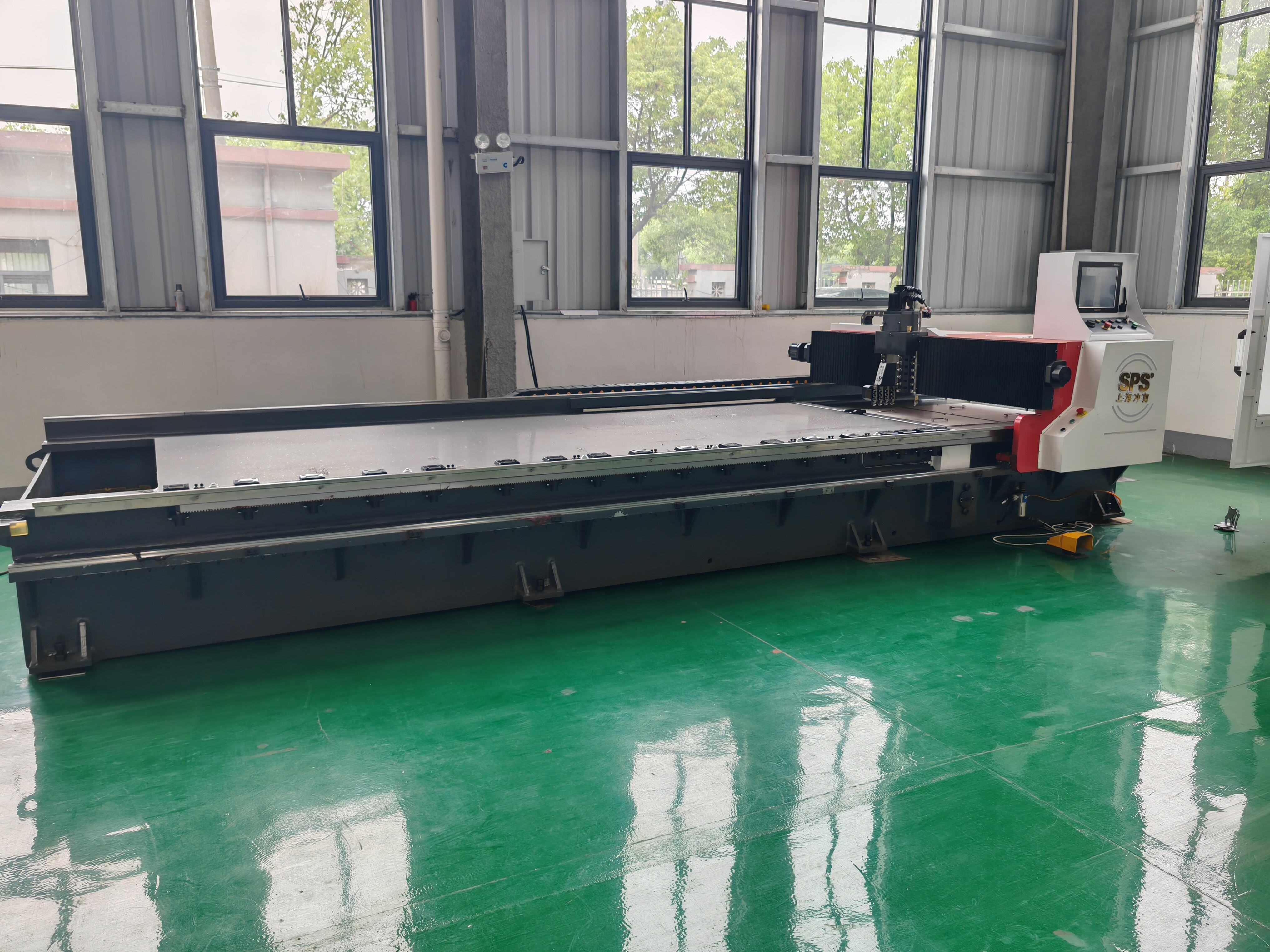

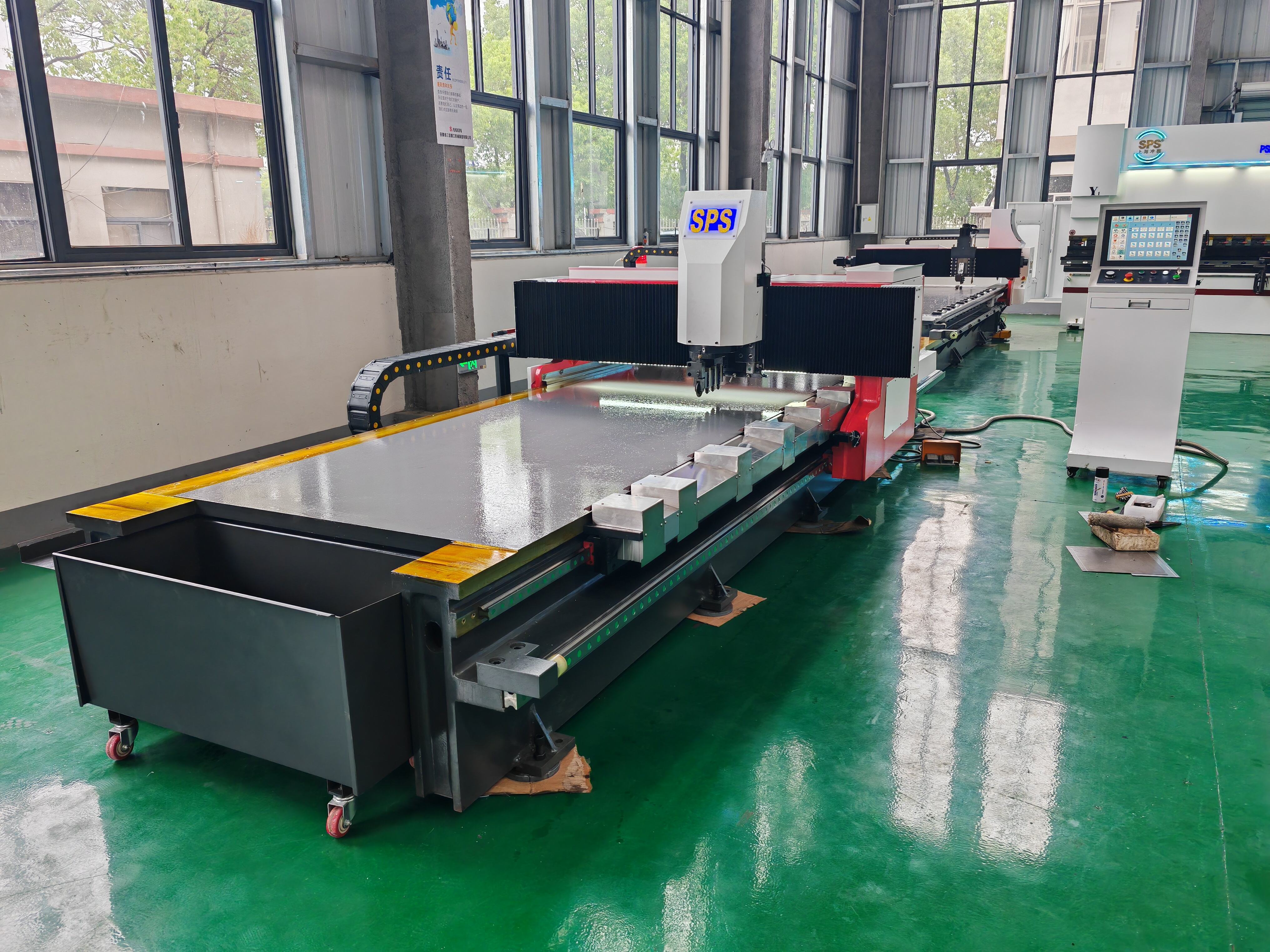

timber cutting machine

A timber cutting machine is a sophisticated piece of industrial equipment designed to efficiently process raw timber into precisely dimensioned lumber products. These machines integrate advanced cutting technology with automated control systems to deliver accurate, consistent results in wood processing operations. The core functionality includes high precision blade systems that can perform various cutting operations, from straight cuts to complex angular cuts, while maintaining exceptional accuracy. Modern timber cutting machines feature computerized numerical control (CNC) systems that allow for programmable cutting patterns and automated material handling. They are equipped with safety features such as emergency stop mechanisms, blade guards, and dust collection systems to ensure operator protection and workplace cleanliness. The machines can handle different timber sizes and species, making them versatile for various applications from furniture manufacturing to construction material preparation. They typically incorporate feed control mechanisms that optimize cutting speed based on material density and thickness, ensuring optimal cut quality while maximizing productivity. Advanced models often include features like automatic blade tensioning, precision measurement systems, and digital displays for real time operation monitoring.