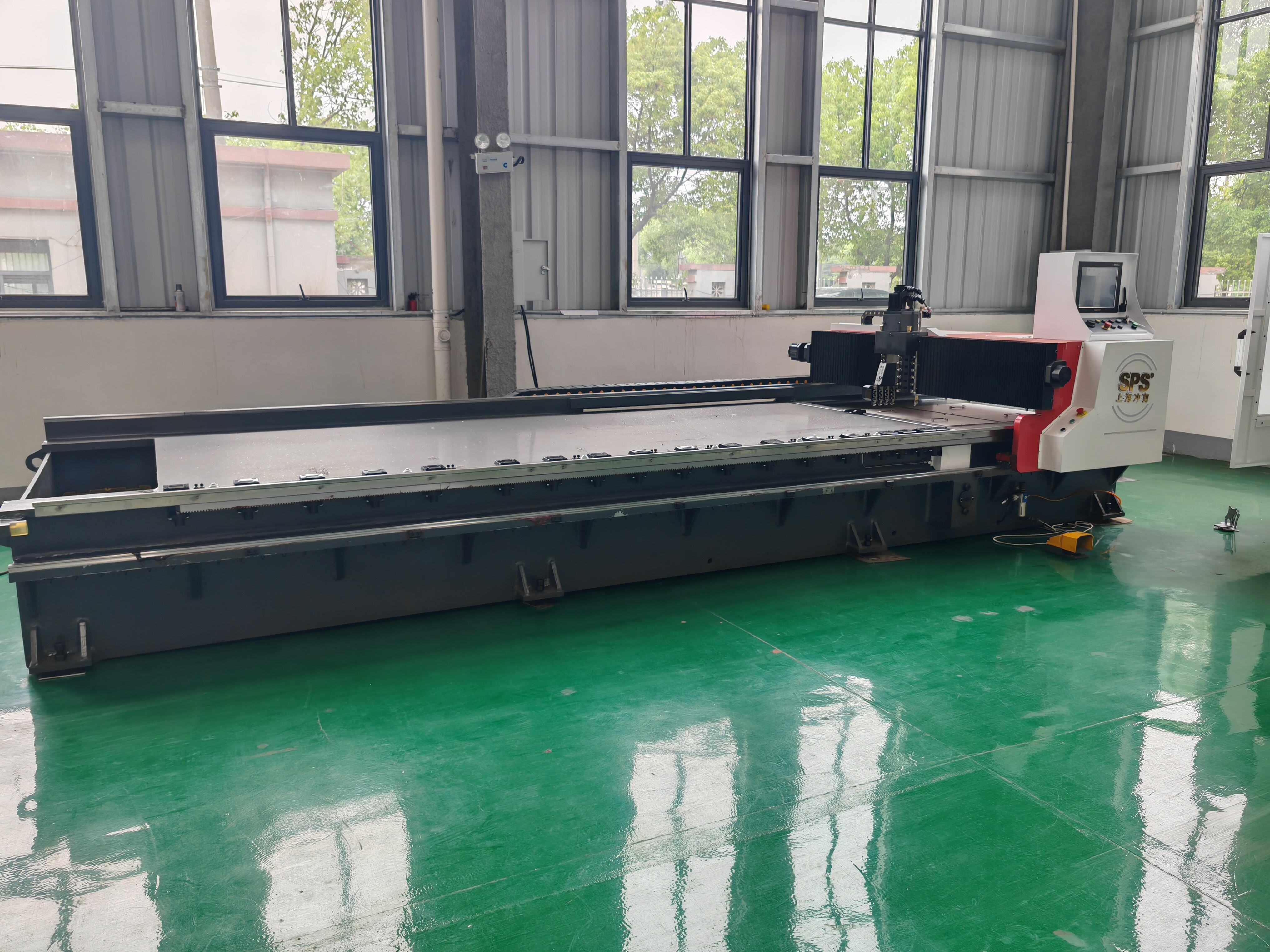

asphalt cutting machine

An asphalt cutting machine is a specialized piece of construction equipment designed to create precise cuts in asphalt surfaces for road maintenance, utility installations, and infrastructure projects. This powerful machine utilizes diamond-tipped blades that rotate at high speeds to efficiently cut through tough asphalt layers with remarkable precision. The machine features adjustable cutting depths, allowing operators to achieve cuts ranging from shallow surface scoring to deep penetration required for full-depth removal. Modern asphalt cutters are equipped with water cooling systems that suppress dust generation and extend blade life by preventing overheating during operation. The machine's robust frame and ergonomic design ensure stability during cutting operations, while its self-propelled mechanism reduces operator fatigue and increases productivity. Advanced models incorporate electronic control systems that maintain consistent cutting speeds and depths, resulting in clean, professional cuts. These machines are essential for road construction companies, municipal maintenance departments, and utility contractors who require precise cutting capabilities for various applications, including road repairs, expansion joint installation, and utility line installations. The versatility of asphalt cutting machines makes them indispensable for both large-scale highway projects and smaller residential road maintenance work.