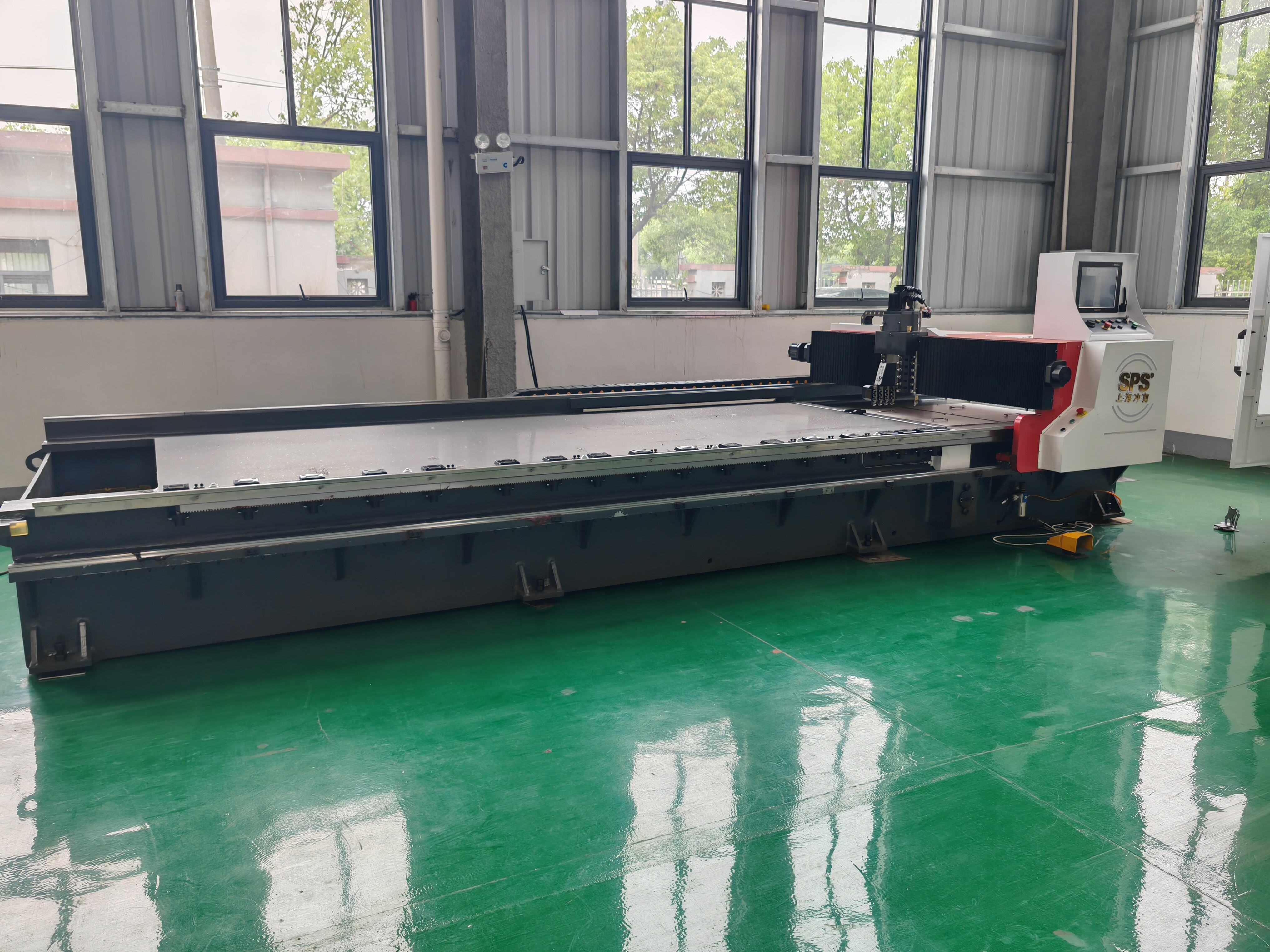

tea cutting machine

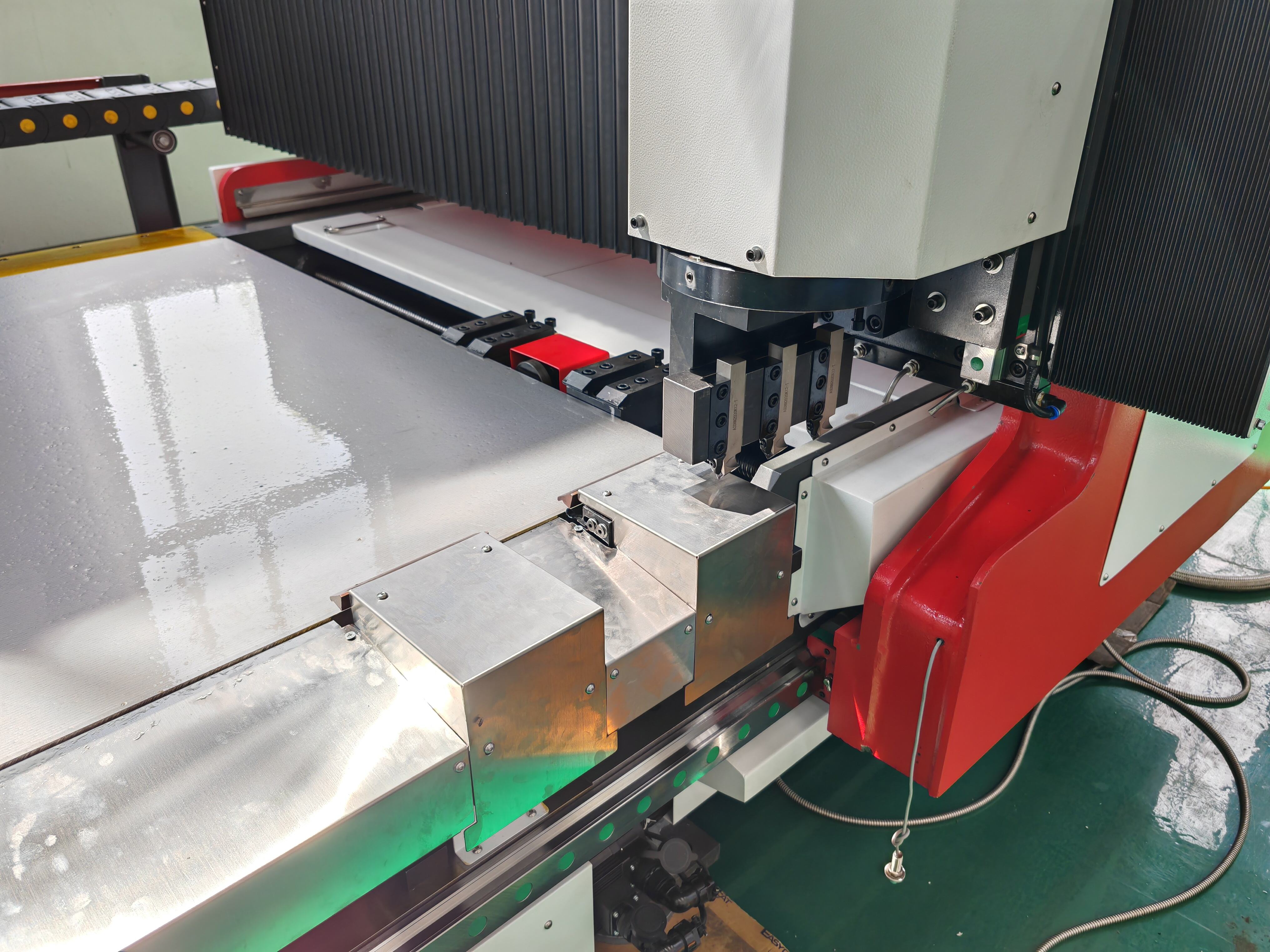

The tea cutting machine represents a significant advancement in tea processing technology, offering precise and efficient cutting capabilities for various tea varieties. This sophisticated equipment utilizes advanced blade technology and customizable settings to process tea leaves into uniform sizes, ensuring consistency in the final product. The machine features a robust stainless steel construction, incorporating multiple cutting mechanisms that can handle different tea leaf types, from delicate green tea to more robust black tea varieties. Its automated feeding system maintains a steady flow of tea leaves, while the adjustable cutting speed allows operators to optimize processing based on specific requirements. The machine's cutting precision ranges from 1mm to 20mm, accommodating diverse market demands for tea particle sizes. Safety features include emergency stop buttons and protective covers, ensuring operator safety during operation. The tea cutting machine's versatility extends to processing both fresh and dried tea leaves, making it an essential tool for tea manufacturers of all sizes. Its efficient design minimizes waste and maximizes yield, while the integrated cooling system prevents heat damage to tea leaves during processing. The machine's digital control panel enables precise parameter adjustments and monitoring of the cutting process, ensuring consistent quality output.