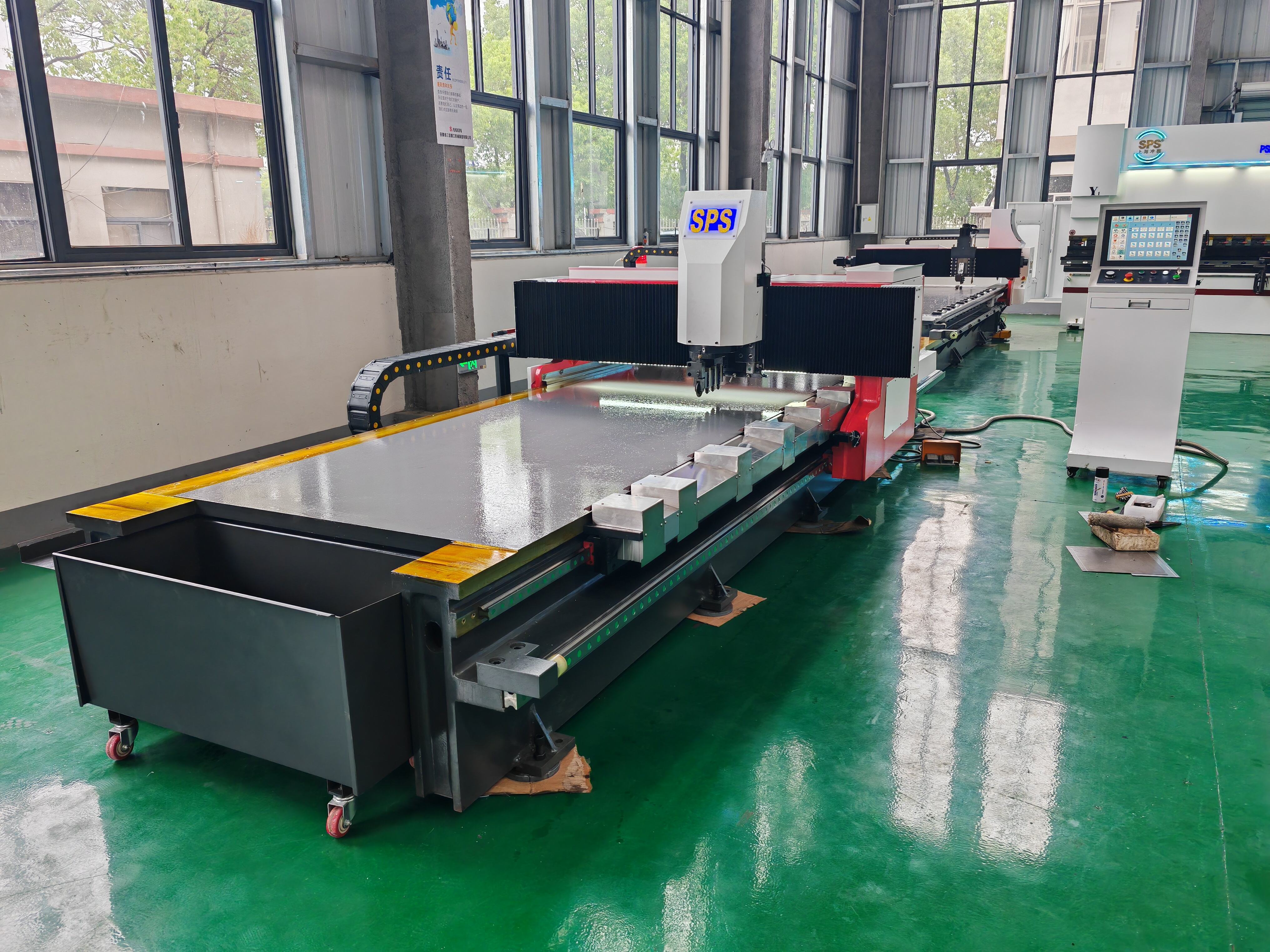

industrial fabric cutting machine

The industrial fabric cutting machine represents a revolutionary advancement in textile manufacturing technology. This sophisticated equipment utilizes precision engineering and automated systems to deliver accurate, efficient, and consistent cutting results across various fabric types. The machine incorporates advanced features such as computer-aided design (CAD) integration, automated material feeding systems, and multi-layer cutting capabilities. Its cutting mechanism employs either ultrasonic technology, laser cutting, or high-speed rotating blades, depending on the specific model and application requirements. The system's intelligent software allows for pattern optimization, minimizing material waste while maximizing cutting efficiency. These machines can handle diverse materials, from delicate silks to heavy-duty industrial textiles, maintaining precise cutting tolerances throughout extended operation periods. The cutting process is fully automated, with built-in safety features protecting both operators and materials. Modern industrial fabric cutters also feature advanced tracking systems that monitor cutting progress and material usage, providing valuable production data for optimization and quality control purposes.